Archify Connect: Introduction to Ezibilt

Archify Live is our web series that responds to the increasing demand for virtual learning and networking. Our latest session was held on the 15th of June 2023 and was presented by Moddex. Below is a transcript of the presentation.

Our topic today will be the Introduction to Ezibilt.

Just a brief introduction to Moddex. A lot of you probably would have heard of us before, but we are Australia and New Zealand's leading manufacturer of crockery and pre-engineered handrail and balustrade systems. So, systems are tailored and designed for commercial and industrial markets. There's a range of systems we've got from your basic handrails to your full balustrade and engineered bridge barriers. Recently, we've developed a new system we'll call an Ezibilt, which is a ramp and steer system designed with the same modular attributes as our handrails.

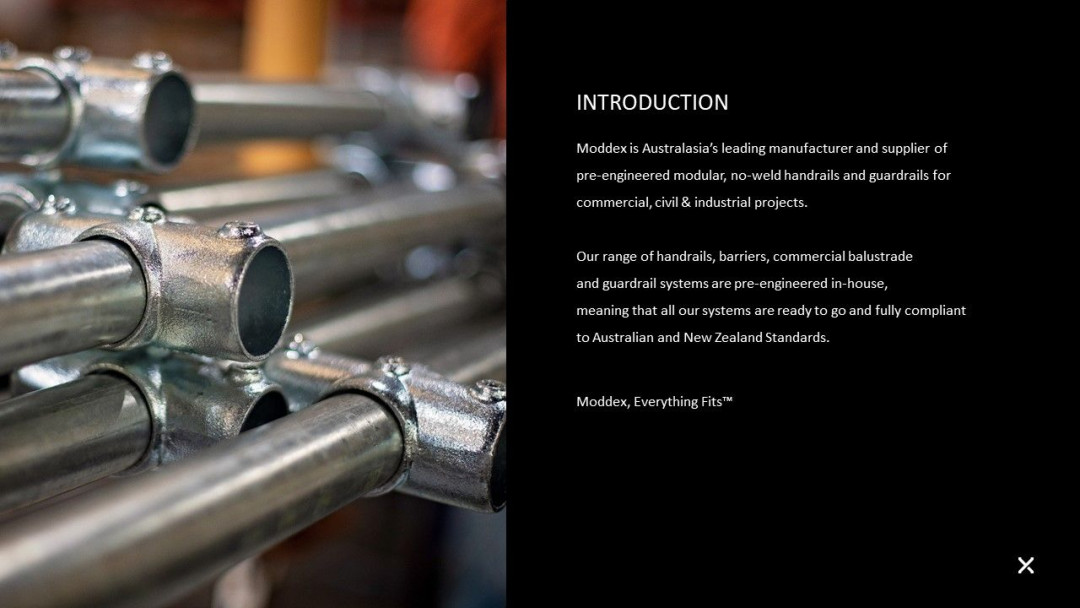

So, the agenda for today quick run-through of our standard products, and then cover a bit on how we can help with specification making that easier and faster for you. How we wrap up the end-to-end design process, from working with architects through to getting a project on-site, but on our certifications and then go into a bit more detail around new innovations and that Ezibilt system.

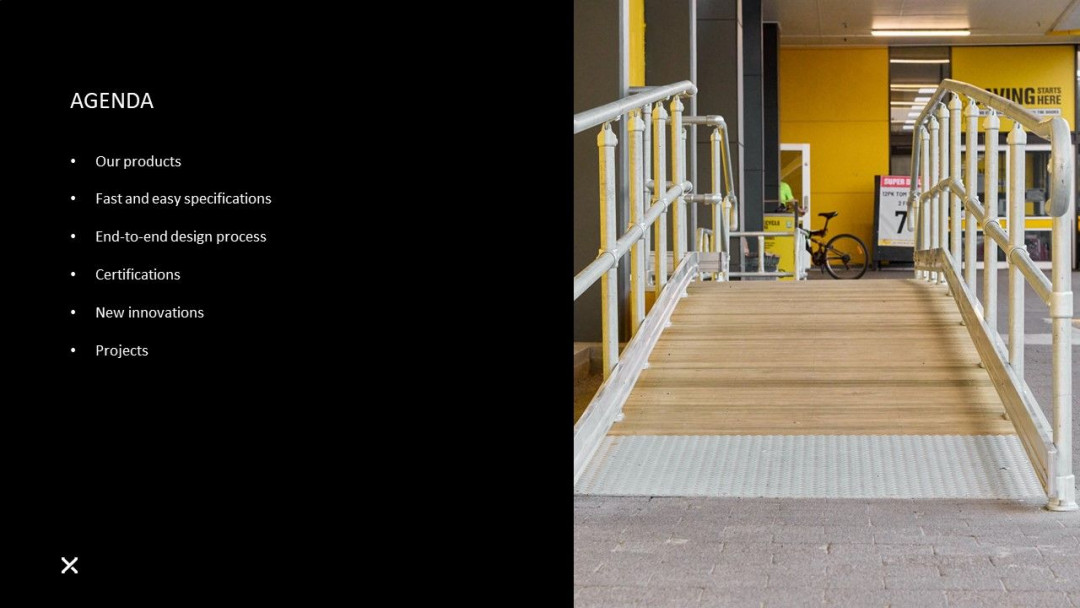

We’ve got a range of product families and then different configurations within those families for handrail and balustrade systems. Just to recap on the main ones for us, you can see here on the screen the Assistrail range, which is designed to meet accessibility coats so you think on your wheelchair ramps and accessible stairs, got a broad range of configurations to cover all those needs. Also got BikeSafe Barriers bikeways and shear paths, and Bridgerail Barriers designed with high loadings. And then Conectabal is another branch we do a lot of it's our balustrade ranch. Anyway, any balustrades fall over a meter and a public space. Then there’s Tuffrail, our industrial handrails, which is used a lot in industrial applications. Now the back of the house and sort of wastewater treatment plants, that type of project. So that's a brief overview of our handrail and balustrade systems. We'll come back to the Ezibilt ramp system shortly.

How we can help out with your specifications and make them easier and faster? We have been counting a full BIM library of all our systems. So that can be downloadable ArchiCAD, Revit and Tekla and more programs. So, yeah, we get a lot of great feedback on these speed-up designs a lot. The system specifying is going to be compliant, and it's going to be engineered. So, it takes away a lot of risk. So to make a BIM library, we partnered with RGS BIM Solutions. So that's a well-known BIM provider from Melbourne, Australia. So, they're well known for their quality of product. We also partnered with NATSPEC. So that's a helpful pill to write up at speaks all affirmations in there. So again, saves a lot of time. Also, on our website, there are a lot of compliance and design guides for our handrail and balustrade systems that just go into detail about the nitty-gritty of compliance. And give partner with key industry partners.

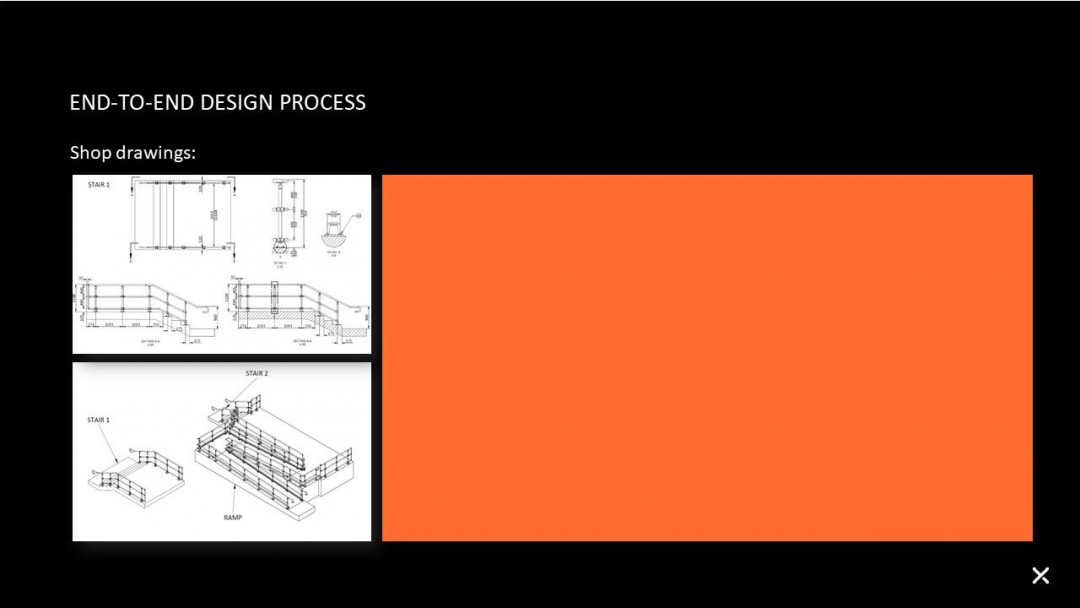

Talking to a design process, and our end-to-end process Moddex with what we do. So, part of our solution, our turnkey solution is doing a design process when we actually go to produce a project. So, this either starts off with a site measure on site, else, we can work off a steel model, or as you can see right there with a video plan. So, prior to manufacturing, any job we do, we do a full set of shop drawings. And they go back to the builder we're working with at the main contractor, and they often send them back to architects for review and sign-off so to just help catch all the finer design details. Make sure all parties are happy with the desired outcome before you go to manufacturing.

Also got the ISO 9001 for quality and ISO 45001 for safety. Just recently, as of May, we were certified for Great Place to Work.

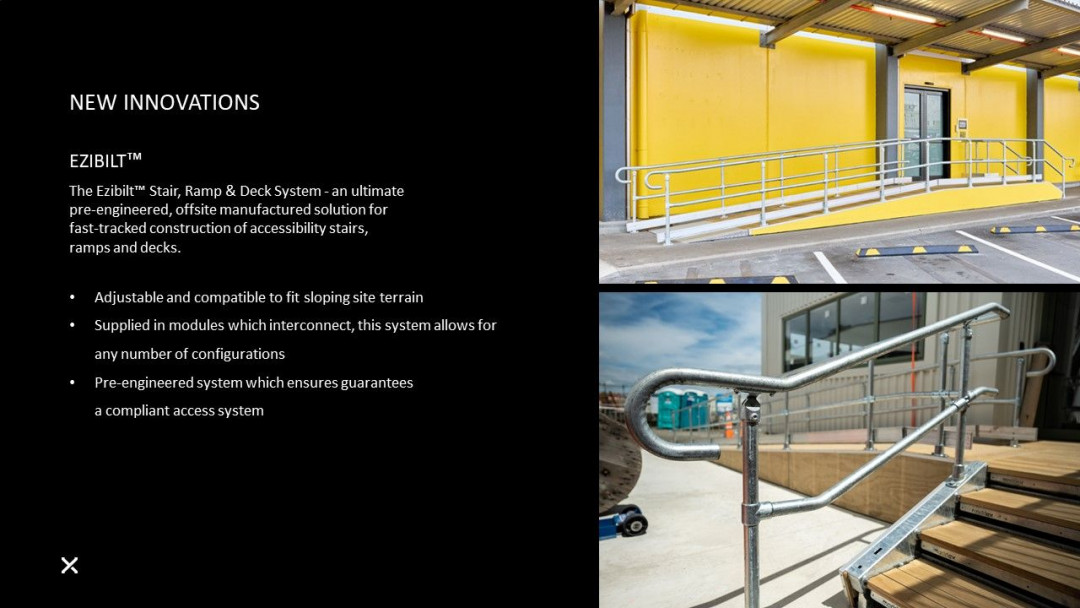

And this is coming to the Ezibilt system we mentioned earlier. So, this is one of our new innovations. So, the idea is to bring a ramp and steer system that has got the same attributes as our modular, proprietary pre-engineered handrails and balustrade systems. We've tried to take the approach of you know, modular specifiable product and bring that to ramps and stairs. Where this idea came about is we do a lot of projects for schools, especially with the modular school programs, where they bring us modular classrooms prefabricated to the site, landing it, building in the building decks and wrapping around it. And then traditionally would come in measure then once I completed and then manufacture a handrail.

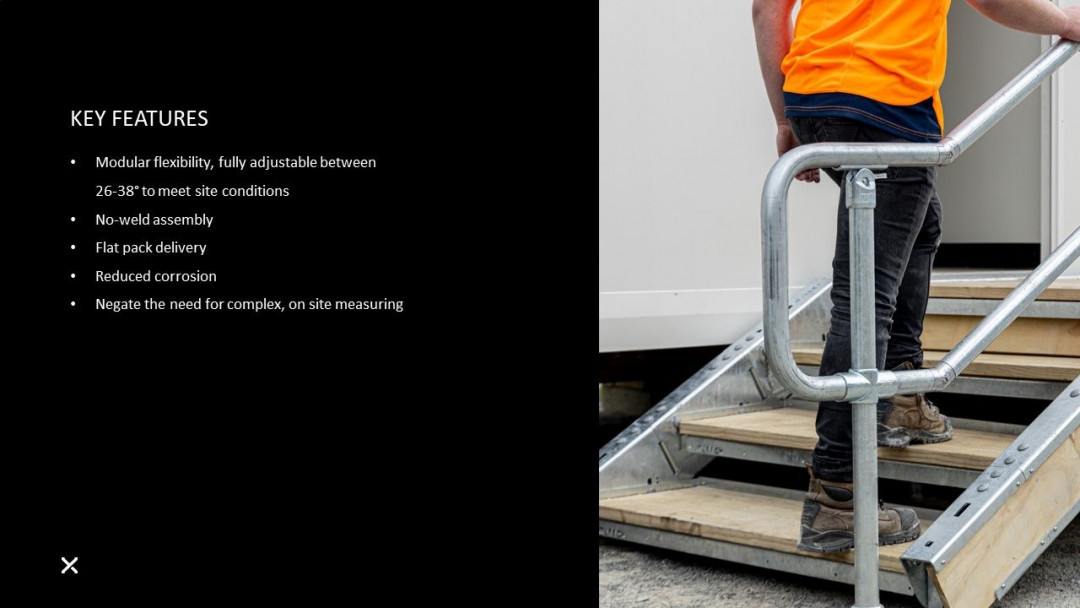

So the idea was with this is it could be landed at the same time as the classrooms and come with our handouts in one package. The idea was to save time and then got the advantages of being a pre-engineered product. So the key feature of this Ezibilt rapid steer product is so flicking that it's got a lot of adjustability and flexibility to make site conditions. The steer, for example, is adjustable between 26 and 38 degrees. It is also a no-weld assembly, so can be easily assembled on-site. No hot works, no permits needed. Another advantage is the delivery. So, we pre-manufacture everything in-house, then it's all broken down and a flat pack delivery is sent to the site.

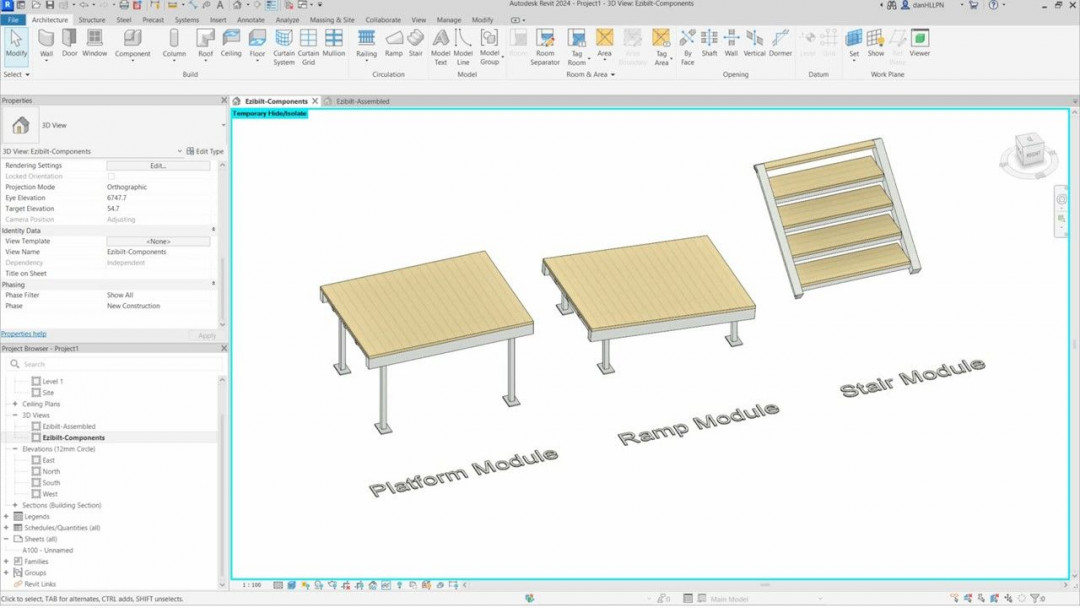

That's what this is just a bit of an animation of how the system works. The way we have designed the system to work is in different size modules that can be configured in different configurations to make the access solution. So, you can see here, it's an example of a solution being been made and the different size modules. The idea of having this system and preset and standardized modules is it allows us to produce it quickly in our factory and have product on hand and stock ready to go. Big advantages with speed and getting product to site quickly. And then still quickly.

The only other benefit of this Ezibilt system is taking out a lot of skilled labour from traditional methods of construction. So, benefits for the builders and construction companies on site as they need less skilled labour. If they had one, skill builder, and then a couple of apprentices under them, this would be an easy enough product to install for them. It also eliminates waste. Because we manufacture everything in our factory under a controlled environment, we're only sending products to the site that is going to be used. So, there'd be no offcuts filling up scrap bins that are keeping that waste very lean. Speed of construction, we've touched on this, having a site and a pre-configured form and a lot of pre-made components along with the design and installation drawings we've done beforehand, the speed of construction is very quick. So, we've had feedback from some of the projects we've done, whether we're around would usually take them no beyond two weeks to construct. By the time they've gone through the process of putting in piles into the ground, constructing the timber, and waiting for shipments of timber to arrive. With this Ezibilt system, I've been able to complete it in a few days. Along with that, we've got a lot of quality control and consistency. The same product is going to arrive on-site, you know, having different builders building across different locations and with varying consistency, it's the same control, no proprietary product for a consistent result and that brings cost savings. Because we are able to manufacture this in bulk reduces manufacturing costs for a cost-effective solution. As well as brings the benefit of fast installation prompts, so saves on labour on site.

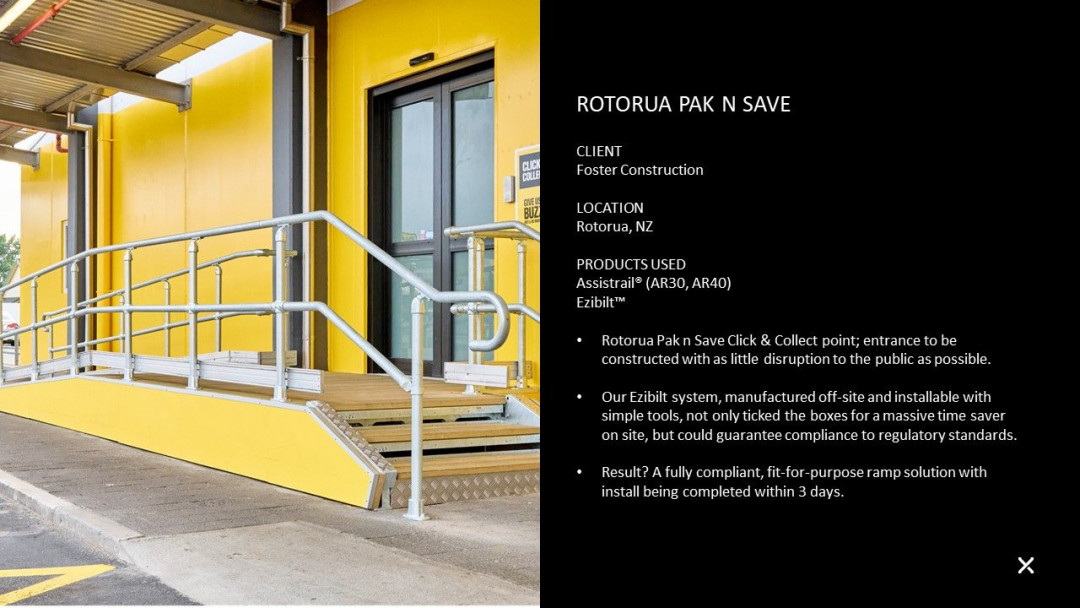

This is talking about a case study of a recent project we've done. So, this was New Zealand at a supermarket. Key aspects of this project were this was a modification to make a Click & Collect zone. So, you can see in that picture, that new set of doors there. They put that in and only had a very short time space to get a ramp and steer in there to make full accessibility coats while minimizing site shutdown. So we're to manufacture a full ramp system. Prior to them starting on site send it to site. They had all the components there ready to go. As soon as they cut the hole in the wall and store the doors. They're able to install the ramp system straightaway and be open within a week. So we're really tapping to the same speed on site and minimizing site shutdown.

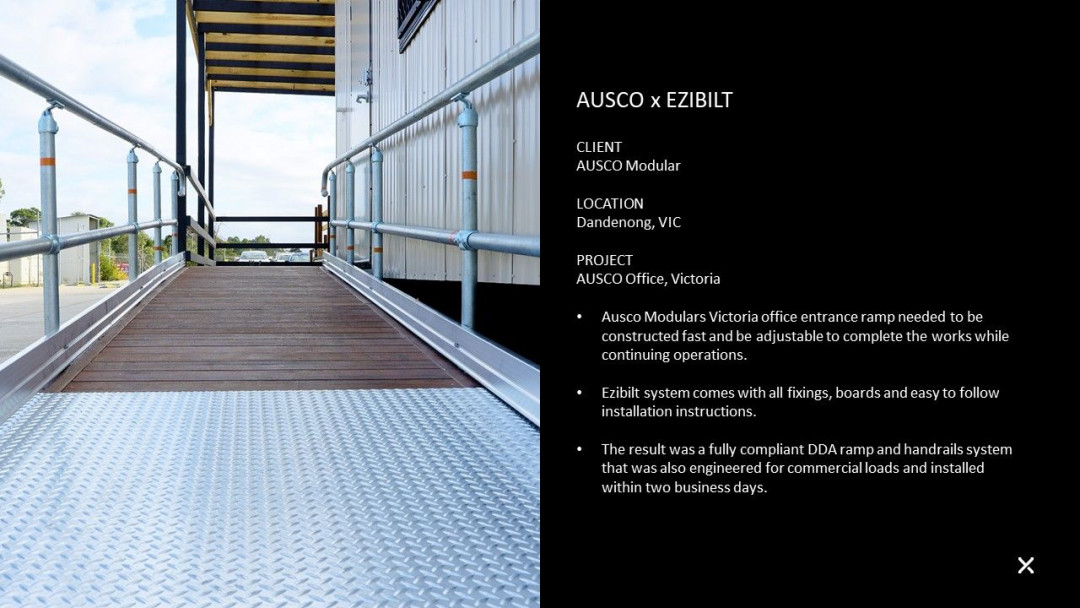

This is a project we did for AUSCO. So, this was at the head office, they were invested in the Ezibilt system and purchased one as a trial. This was installed the same day, as it turned up to the site including the handrails. And again, speed on-site as well as consistent results so they knew what they were getting from the design drawings we've done, turned up so everything there to meet accessibility requirements and done within a day.

This is just a quote from Robert from AUSCO. So he mentioned that the Ezibilt system allows us to offer our clients a modular solution that enables us to get ramps in quickly and also provides a cost-effective solution for compliant access. And they are looking forward to integrating Ezibilt into the branch they provide.

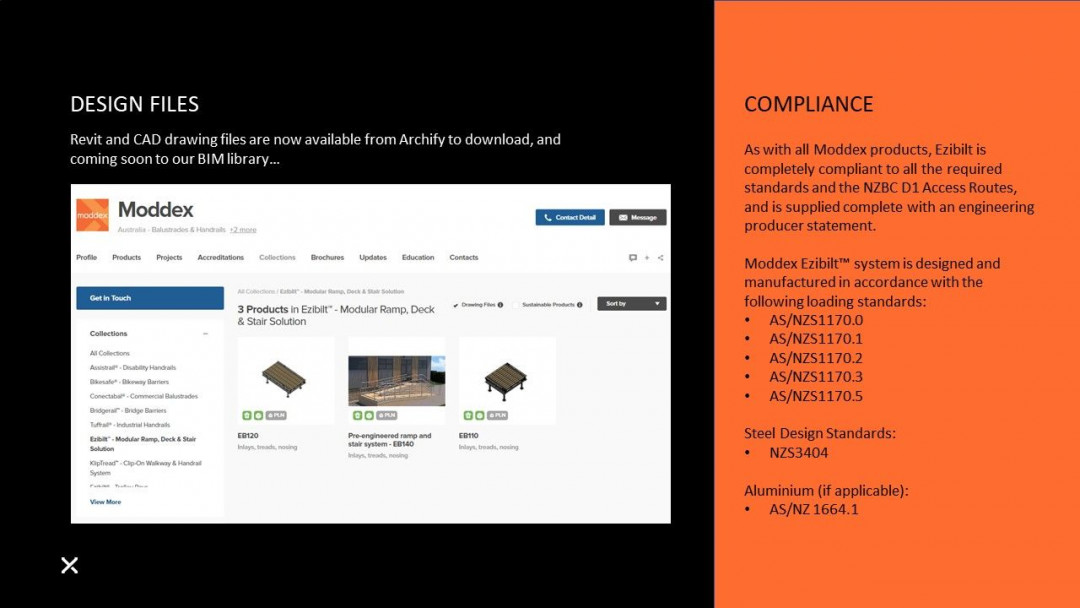

With this Ezibilt system, we have the design files available for it.

So this can go along with our handrail and balustrade boom library we've got currently working together. So this video shows an example that they knew - so you can see the different modules and the module sizes. So as mentioned earlier, it's configured out of different module sizes and 600 mil increments and can be configured in any way you'd like to make the excess solution. We can see in this example, I've put our CB 55 Balustrade system on it.

The room system itself is a steal substructure, it can be created in any type of planning that's required. So whether that's timber or like composite decking products, such as mod wood. And then also now I've had an interest in the likes of FRP grating or micro mesh for superior slipper resistance.

So that's it from us on the Ezibilt product. Happy to take any questions. Got one here in the chat box, from Bill. So asking if the Ezibilt system incorporates verandahs. So at the moment, as it stands, it's not designed to do that, with our initial versions of it. Something we could look at further down the line. But then, with the design process we go through, we could look at incorporating or having them in our design, not actually attached to our platforms. But if they're down the side of them, we could work around with our models work around the post and the set out of them.

We've got a question from Scott, asking about the Ezibult deck system, and if the handrail heights are adjustable to allow for a thicker finish. So yeah, that's the right system. That's something again, we'll wrap up our design process, we do write and manufacture. So we need to make the stanchions or handrail posts slightly longer to allow for a thicker cladding timber, we can do that. And then a lot of the time the handrails will be mounted on top of the finish also. Yep, nosings and that type of thing. Yes, we can wrap this up and what we do, wrap it up and our design and provide. Some clients prefer to get their own contract after we add them. But if it was preferred, Moddex can wrap that up as well. And then a question here is if the Ezibilt system is available in different colours, yes, I'm guessing you may be referring to the yellow picture there. I mean, it's just whatever material you clad it in. So the actual Ezibilt substructure made of steel will be covered up when the roof is cluttered. And yeah, whether that's, you know, and whether it's a concert decking, whether it's FRP product, depending on the colour of that.

That looks like all the questions.

Yep, ask if any other options other than HDG finish. For the ramp system. We currently only have the galvanized steel finish. For our handrail systems, we have a limited range of standard steel in marine grade aluminium, but the bread and butter of what we do are galvanized. We can do powder coat finish something we can do a lot of that there'd be no point doing that on the rent because you wouldn't see it once it's the planning has been added but for the handrail systems and balustrade we can powder coat pretty much any colour you're after. And it does give it a lot more sharper look and feel.

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia