Archify Live: Creating Learning Spaces for the Modern Pedagogy

Archify Live is our web series that responds to an increasing demand for virtual learning and networking. Our latest session was held on the 9th of July and was presented by Glyde Architectural. Below is a transcript of the presentation.

Presenter

I'd like to introduce Marty from Glyde. Marty is your presenter today and will be taking you through this session.

Marty Belcher

Thanks everyone, for joining me today. I want to talk a little bit about creating learning spaces for the modern pedagogy.

Schools have gone through a huge change in the way that they’re used and the way that we educate. And what we need to do is ensure that there's a product range of systems and means to be able to create the spaces that we need in our modern schools.

So I just grabbed a snapshot of VSBA design guidelines, I'm based here in Victoria, so I've grabbed one of our design guidelines here.

“Spaces must be adaptable and support a variety of teaching and learning approaches from team teaching to one-on-one lessons and encourage collaboration between students and teachers.” So that's quite a broad requirement that they've outlined as a goal for education designs. We’re challenged with proving a variety of spaces. And what we're trying to do is create spaces that are adaptable to students physical, cognitive, social, emotional, and sensory abilities. So obviously, there's a broad range of age levels, and different ways that we can teach different types of groups. We want these spaces to be able to promote health and engagement. Be safe and inclusive, empower students to build school pride, and encourage intellectual engagement, as well as being fit for purpose.

Today, I'm going to talk about four main topic areas. The first one is Adaptability. How these spaces can be created, and how we are able to interact and use these concepts in in a real world. We've got some examples and some imagery to be able to share with you.

The second one is DDA compliance. If we're using large format acoustic sliders, we need to ensure that they're still compliant with all of our building codes. We need to definitely take into account DDA compliance.

Thirdly, Acoustics. These spaces need to be usable, but also managed from an acoustics perspective. So separating spaces, as well as management of sound within the spaces that we're creating.

And the fourth topic is Safety. So when we're talking about some of these different systems, we need to make sure that the end user group is kept safe, in every way.

First of all, I'm going to talk about adaptability. So, it's Designing Spaces with purposeful flexibility.

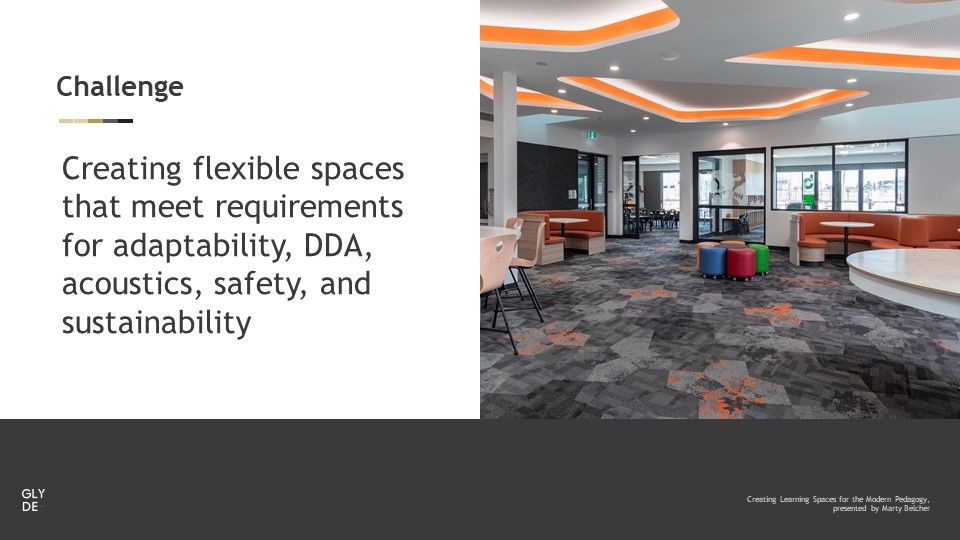

So how do we do this? I’ve identified the challenge for us. We need to create flexible spaces that meet the requirements for adaptability, DDA, acoustics, safety and sustainability. In the picture that you see here, you get an idea of where I'm coming from by looking at the large format glass sliders in the background. It's about linking spaces with the areas external from a standard, more traditional GLA area into these open plan areas where smaller group activities can take place.

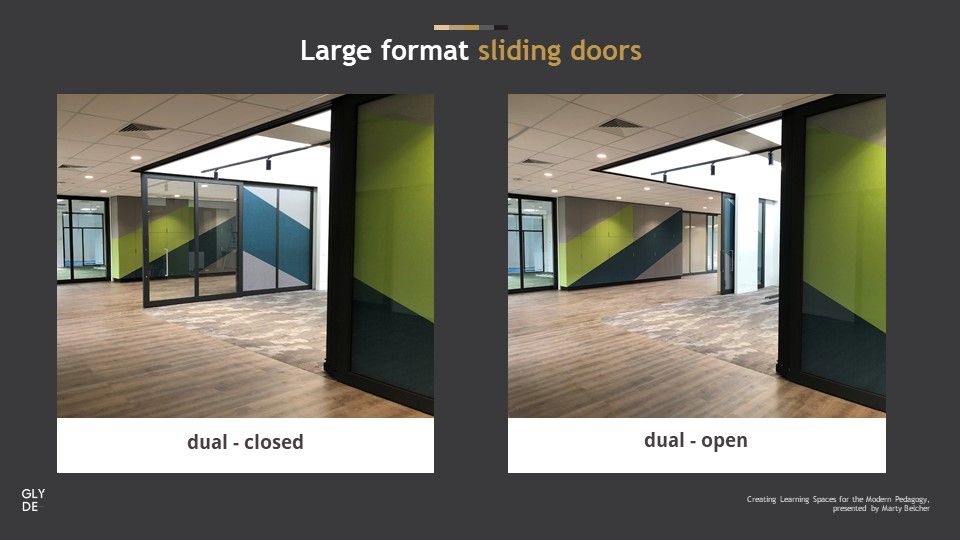

One of the ways of being able to provide those solutions is through our designs of large format sliding doors. These have been designed with performance criteria, ease of use they're manually operated, they're acoustically rated, they're safe and they provide flexibility to configurations. They can be in glass or solid finishes. These doors are easy to operate.

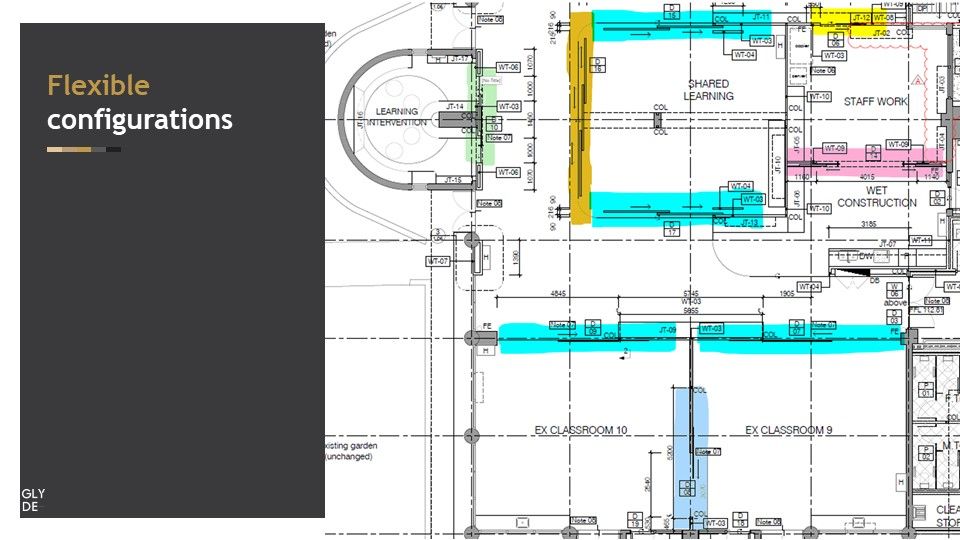

The configurations that we can achieve with these are kind of limitless. I've grabbed a snapshot of a floor plan of a school that we've recently done some works in and highlighted some of the door systems where they’re linking classrooms, to shared learning spaces and learning streets. And I've got some imagery to go with this, so that we can sort of get some idea.

The blue highlight areas are jewel acoustic sliders, and you'll see them shortly. The mustard/orangey/goldy colour one is a large triple slider, and they're more of a floating screen scenario, so that shared learning space can be opened right up. The green areas are smaller format acoustic sliding doors, which screen off a learning intervention area where smaller group activity can take place or one on one interactions. And the yellow space is just a single slider that's actually used to link a staff area. And the pink one we'll have a look at shortly, is a dual cavity slider which is also bi-parting. And you'll see what that looks like shortly as well. So you can see we use a variety of different doors to link spaces and create an easily reconfigurable footprint in our schools.

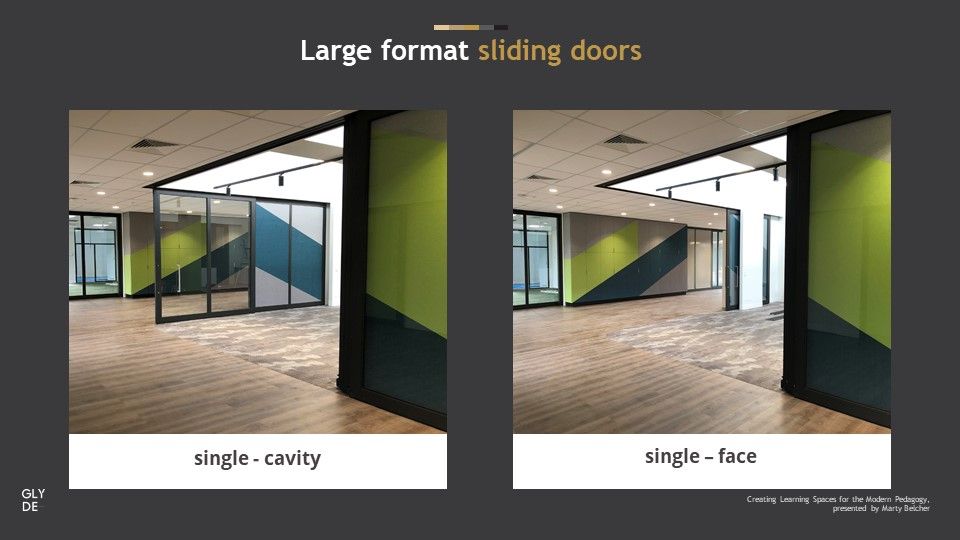

Some of the formats of doors I'll have a quick look at now. We can do single cavity sliding doors. As you can see on the left hand side, the cavities created by building two walls and leaving a gap between them for our door to slide into. The doors can also be face mounted. You can see that the image on the right hand side has got a built in pelmet detail. And that door simply slides along the adjacent wall. And we'll talk about the acoustics shortly. But either one of those configurations doesn't affect the acoustic performance at all.

These are images of that area that I described before where there's a breakout zone where they can be one on one interactions or smaller group activities. These doors are a lot smaller but still high acoustically rated. The configuration easily manages the space in the most efficient way, in that we don't have to provide for swing doors in this area. It's easy to operate and creates the most amount of flexibility in that space.

The same floor plan that I showed you before. This is a shared learning space that was in the middle of that floor plan. And then on the left hand side you can see there's a dual slider. The first one of those is a glass slider, and the second leaf has pinboard fixed inside the perimeter frame. That dual slide on the right hand side you'll see slides along the wall, there is a sort of a half cavity created by the existing building structure, so inside that wall there is some columns for the above raised roof area.

That same system on the left hand side closes on to a triple floating slide up and bi-parts at the corners. So we've got an acoustically sealed 90 degree corner junction with the doors that slide apart and be bi-parting. The system that I alluded to before, the pink one, is on the right hand side where we've got a dual bi-parting cavity slider and this one too, has pinboard inserts in it rather than glass.

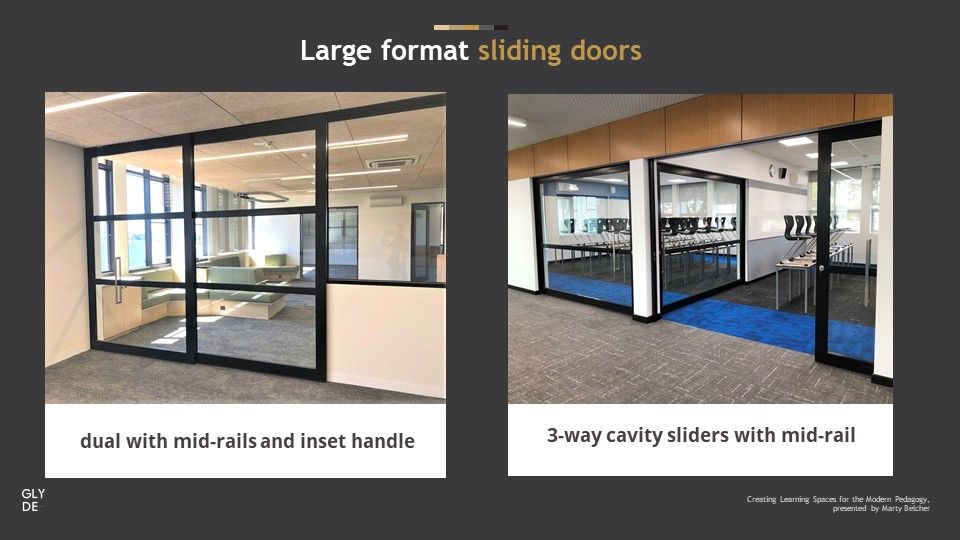

Some more formats of doors as examples. On the left hand side, we've got a dual slider, we've incorporated mid rails in this particular system. The mid rails can be used in lieu of manifestations. So that's a design format that also allows us to use different glass types, where we can incorporate various types of glass, determined by the size of glazing areas, ensuring it's still code compliant. This particular door has got toughened glass in it and you'll note that because the handle is located inset from the leading style of the door to give us DDA compliance on that particular system. The picture on the right hand side are entry doors into a couple of GLA's, and then there's a third sliding door that splits those two GLA’s, they're all cavity sliders in that particular installation.

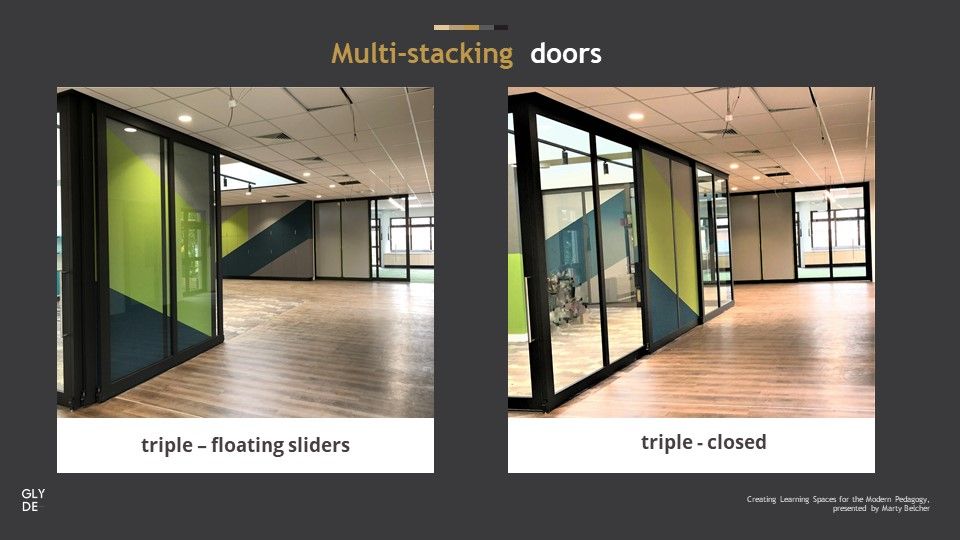

I’ll refer back to that floorplan. Sorry! I'm jumping around a little bit, but the triple floating doors are pictured here. And please forgive some of these pictures it was taken in the latter stages of an installation process. What we've featured here are three acoustically rated large sliding doors, two glazed ones and a solid door. And those panels are floating so they can stack anywhere across that line of doors there and create different spaces for different needs.

We'll jump on to DDA compliance now, because a lot of these doors are used for entry areas, into classrooms. So where sliders are used to move in and out of classroom areas, we need to make sure that they're compliant.

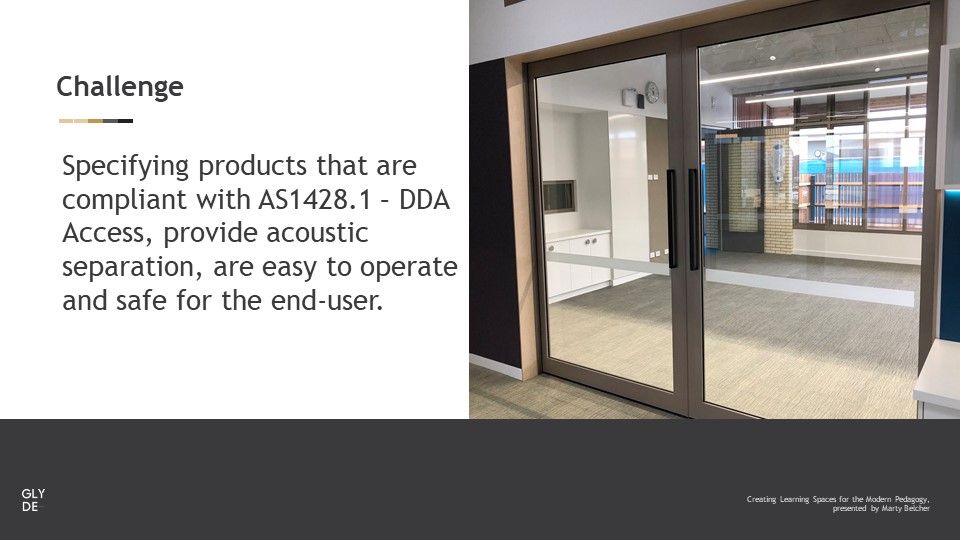

Our challenge with the DDA compliance is to specify products that are compliant with AS1428.1 for DDA access, and they also provide acoustic separation, they're easy to operate, and they're safe for the end user. All of these things are very difficult to achieve in sliding doors. Because as soon as we want larger format doors, they become quite heavy. And then ensuring the force requirements for these doors to be operate is a real challenge.

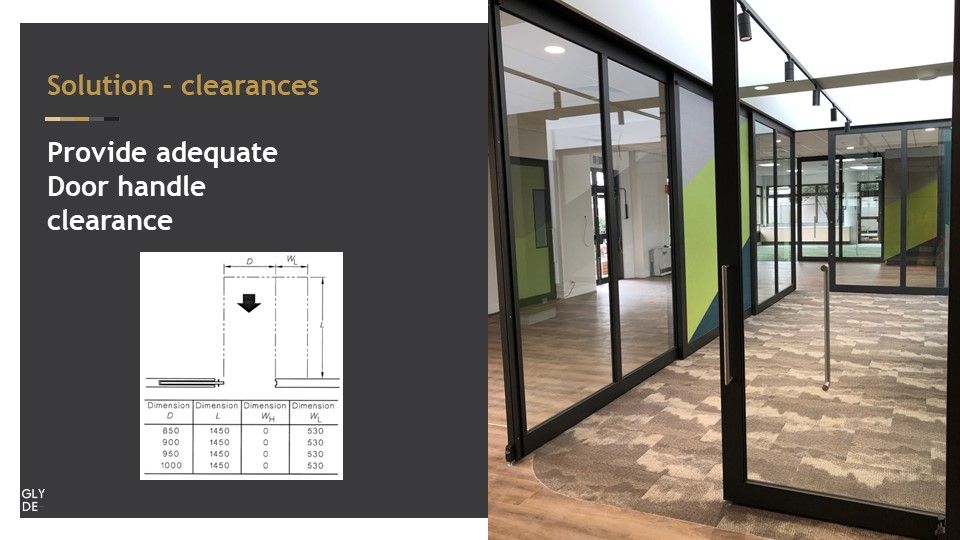

Width of our clearances. That's what we're talking about here, is clear access to the hardware for the door. When we're talking about DDA compliance, on the left hand side, you’ve probably all seen this type of image where we need to create these clear zones for easy access to the door hardware. On the right hand side I’ve used that same school illustration, just outlined how we can achieve these with our handle locations. So the large slider has a handle on the outside of that door, located in leading style because there's nothing around that area that prevents wheelchair access to get to that handle location. Whereas on the inside of that room, when the triple sliders closed, the handle needs to be inset 530mm minimum to be able to get clear access to that handle. So we can still achieve that with these types of sliding doors. The handle locations can also help when we're talking about creating clear openings. So it's getting a little bit into design detail. But if that particular slider was sliding on the inside face of a wall, because the handle in the outside style is towards the front of the slider on the inside, the handle location won't clash with that adjacent wall so that we can create the widest possible clear opening with the door.

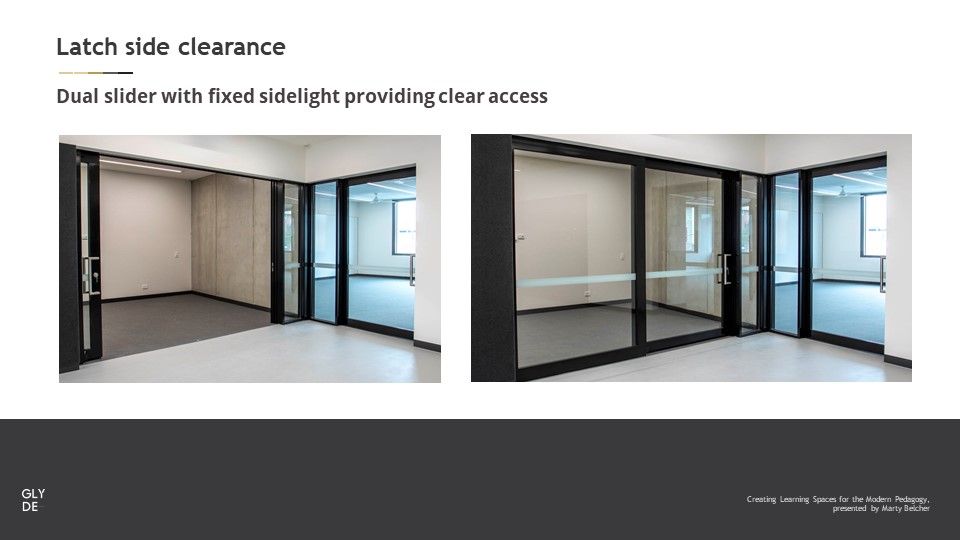

The other way of doing it, and we need to be mindful of when we're talking about clear access to hardware, that also includes locks that are incorporated into sliders, is to create a 530 wide sidelight. So that that handle is still in set the 530mm, but we've also got access to any lever handles or key locks for closing off and making these doors secure. This is a second way of achieving the latch side clearance.

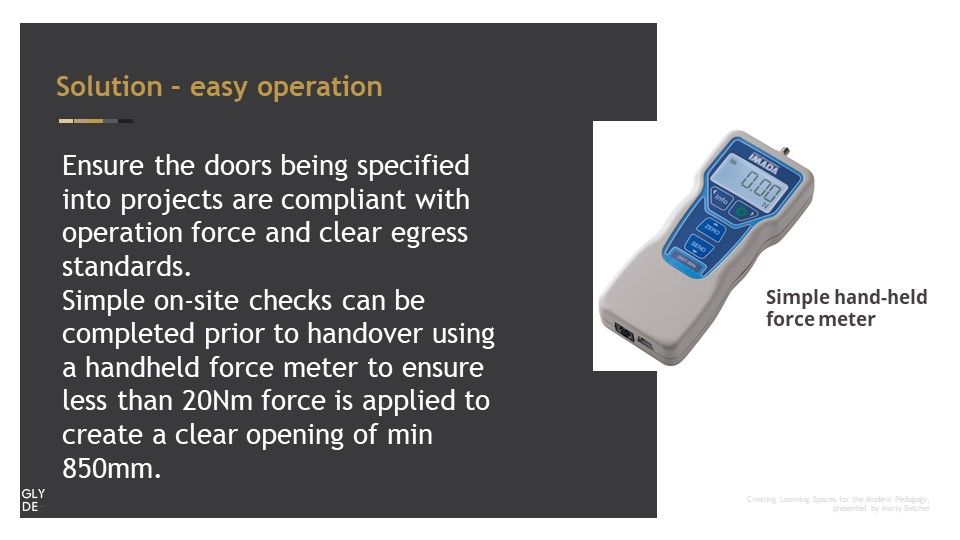

The other part of DDA compliance, we see which is very tricky to achieve is our ease of operation. So that's about the Newton force to open these large sliding doors. We measure that with one of these simple handheld force meters. You push that against the handle of the door and you keep pushing it until you've achieved a clear opening of a minimum of one meter. But it is actually slightly narrower than that. But if we can achieve a meter clearance you now sliding doors with less than 20 newton meters of force and the handle location of course is compliant then we can make sure and sign off that these doors are actually DDA compliant, that with acoustic performance and large doors, like I said before, is very tricky to achieve. But with our design team here at Aluminium Industries we've been able to do that and ensure these large sliders are compliant in all the installations.

Acoustics play a very important part in schools. There is a very tight design guideline as to what needs to be achieved when we're talking about separation of spaces. And I’m going to talk a little bit through both types of acoustic performance. So we need to acoustically separate them, we need to try and visually connect our spaces, which is where these doors come into.

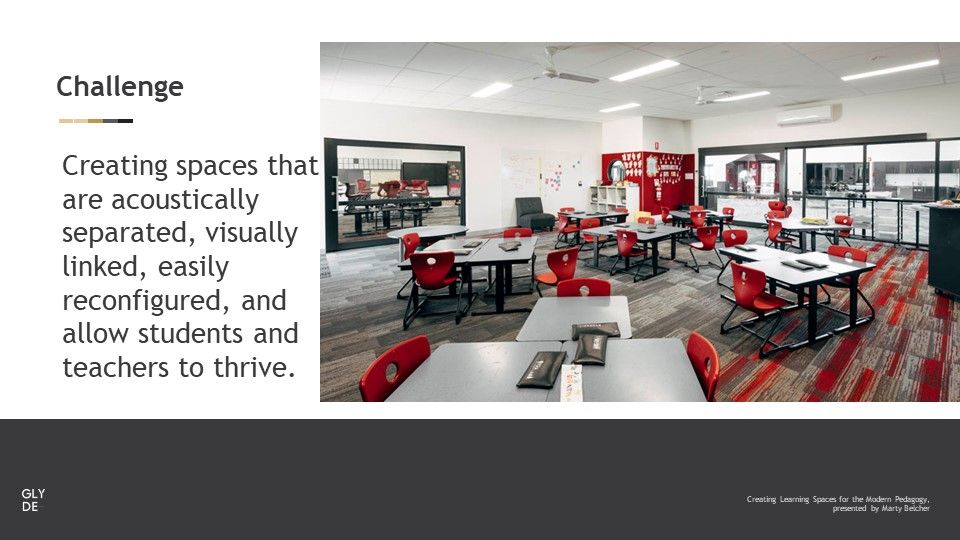

Our challenge here is to create spaces that are acoustically separated, they're visually linked, easily reconfigured, and allow students and teachers to thrive in the spaces we create. The image that I've captured here, is of a new VSBA school. And you can see on the right hand side, there's a large glazed sliding door and also adjacent fixed glazing, that opens out on to a learning street or multipurpose learning zone in in that particular building. So what happens there is that teachers can have visual connection with group activities or with adjacent classes to see what's going on in in those sorts of zones, as well as being able to acoustically separate them. And I'll talk about that a bit more shortly. The door on the left hand side is a glaze cavity slider that's separating these two GLAs, two made out of glass, so that the teachers have visual connection between those rooms. By simply sliding open that door, they can be larger group activities, or zones where teachers can interact with different classes to ensure, to cover off the teachers arm if they have to leave the classroom for any particular person, purpose. And that's all around our flexibility with the way that we teach. So they may need to be times where teachers cover off both classes. And while that particular other teacher goes off and does management of a small group or a one on one type activity.

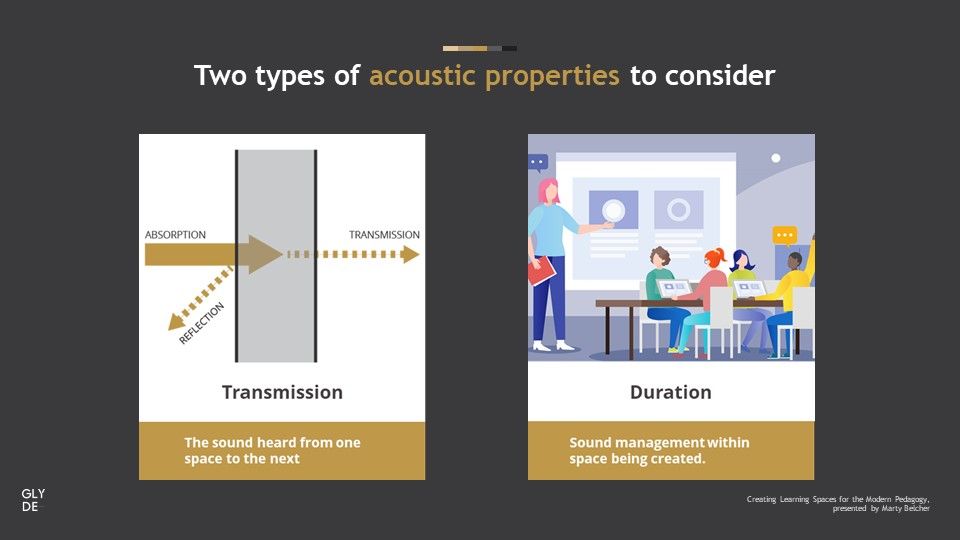

When we're talking about acoustics, there's two particular streams that we concentrate on. The first one is transmission. So that's simply stopping the noise from moving from one zone to the next, and duration, which is the management of our spaces within the spaces that we're creating.

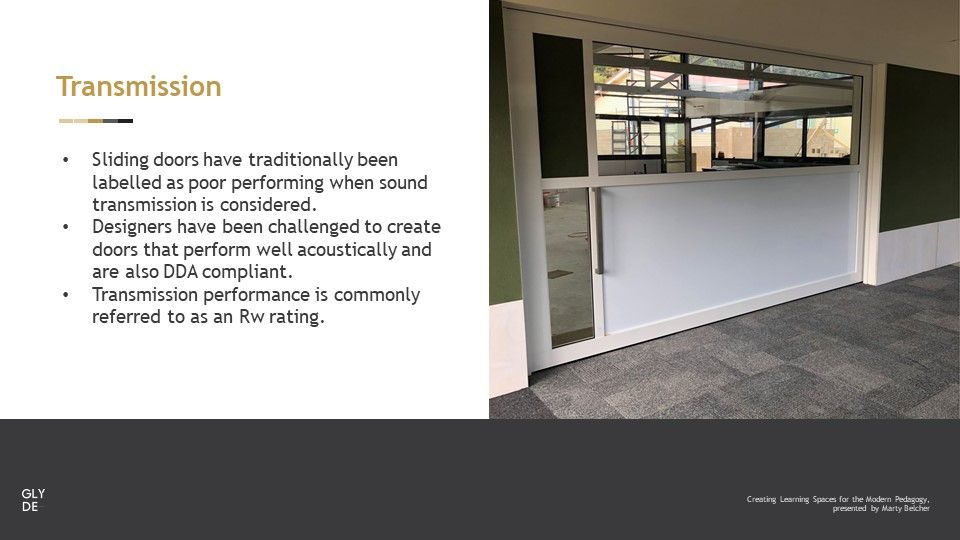

With transmission. Sliding doors have traditionally been labeled as poor performing when sound transmissions considered. So we’ve been set a challenge to create doors that perform well acoustically, but still remain DDA compliant.

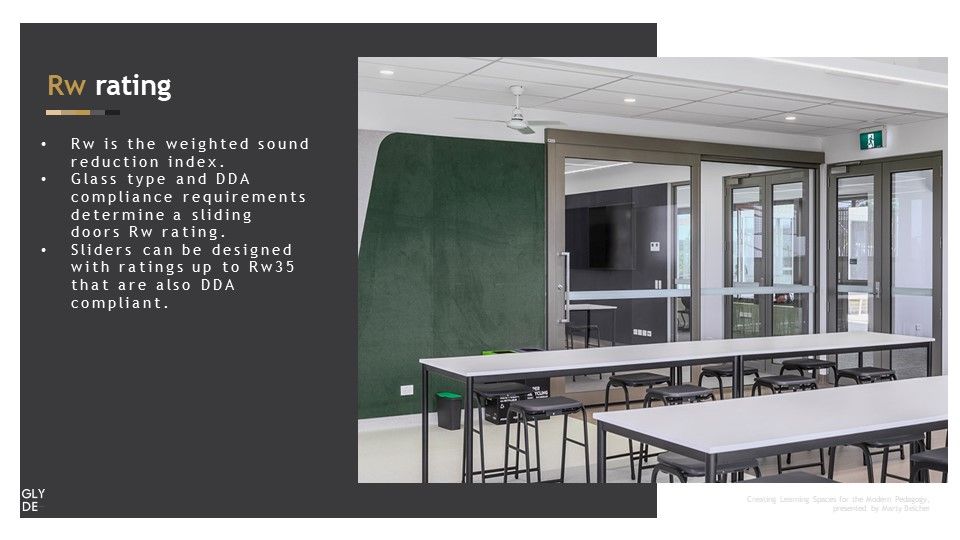

Transmission performance is commonly referred to as an Rw rating. So that's a sound reduction index. I'll talk a little bit more about that the Rw rating is the weighted sound reduction index. The glass type and DDA compliance requirements determine a sliding doors Rw rating. So what I'm referring to there is that the size of the door and the glass type, or solid infill type will determine how heavy the door is. And there's a direct correlation between weight and acoustic performance. So we're going to come to a happy medium where we're achieving a good acoustic performance rating, but not making these doors so heavy that they can't be operated with within that 20 newton meters of force. We've got a range of doors that are rated and certified up to Rw 35 that are DDA compliant. So obviously, the size of the door greatly affects like I said before the amount of force that we need to open these doors for compliance.

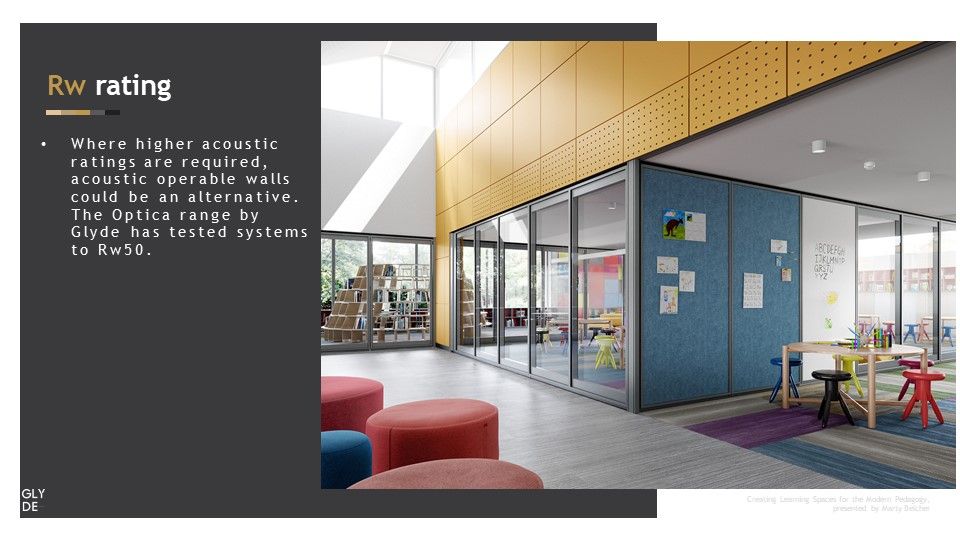

Where higher ratings are required, then operable wall systems do become an option for us to ensure that higher systems can be incorporated into schools. So where spaces might be separating a standard GLA from a music space, or simulate that we can incorporate a operable wall system. You can see here from this image that operable walls can be finished in solid or with glazed inserts. So you can still get that visual connection but just with a much higher acoustic performance. Obviously, they're not quite as easy to operate all day every day from an opening and closing perspective, which is where acoustic sliders come into their own.

I’m going to talk little bit about acoustics and the benefits of glass in our design platforms. Glass creates a physical barrier to the transmission, it provides visual connection and it has the benefit of a subconscious influence on our behaviors. What I'm talking about there is that when we can see what's going on, on the other side of a wall, that humans automatically alter the way that they behave, their voice patterns, and especially their volumes as to what's going on in the spaces around them. So that's where real benefit of glass comes in into schools .It allows natural light into these internal zones as well. So where we have these internal learning streets or flexible zones, where smaller breakout groups can happen, rather than being dark, dingy areas by using glass and especially fixed side lights with glass in them and glass sliders, were able to bring natural daylight into these zones for the well being students as well.

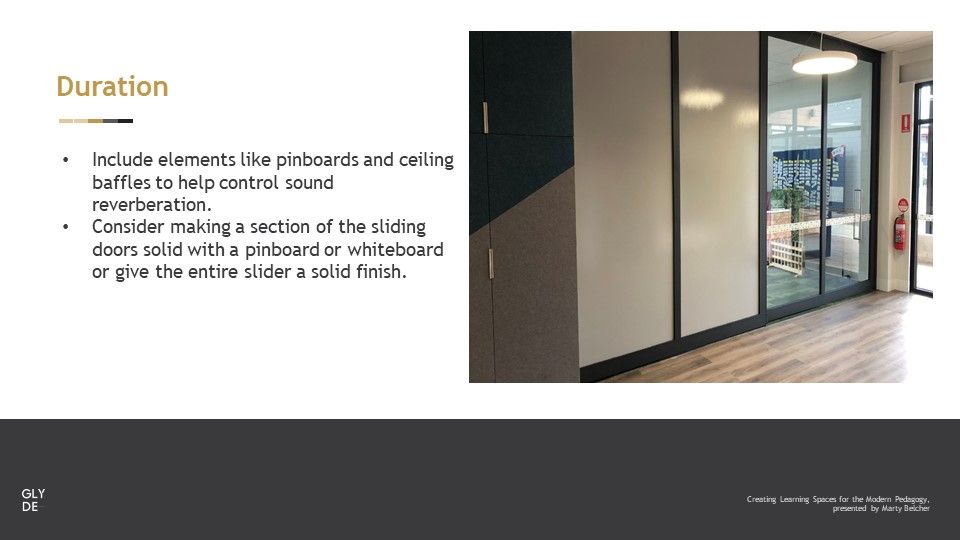

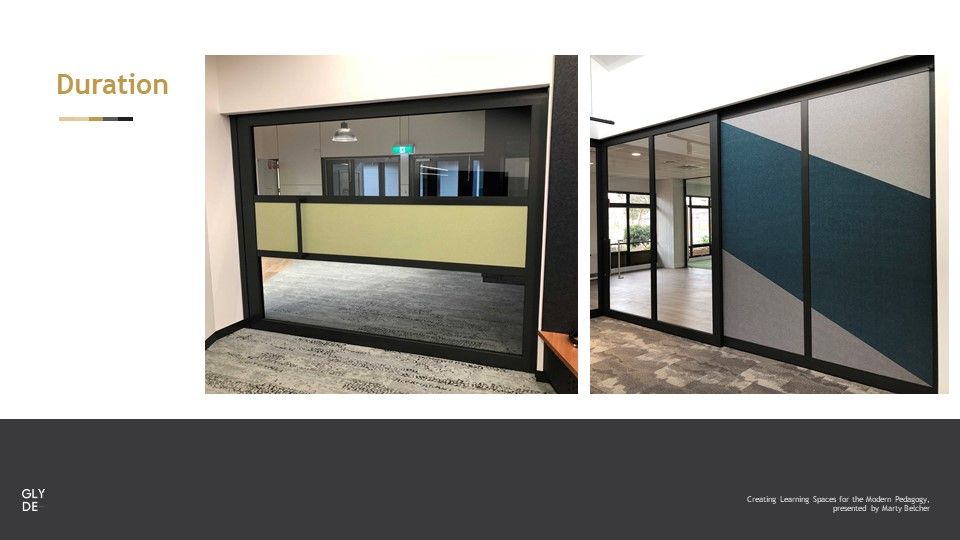

The other part of acoustics is duration. Durations are all about management of sound within a space. Acoustic sliders can incorporate glass and solid infill panels, which can help with sound management. So the picture that I've got here on the right hand side is once again going back to that school, that I highlighting in the floor plan. This is a dual slider that's leading into a client into a GLA classroom. The first leaf on the right hand side is a glazed slider, it's a little bit hard to pick up from this photo, but it is a the second leaf is those gray insert panels. That's actually a painted finish. It's a whiteboard paint that's magnetic. And I couldn't believe how many layers of paint they had to actually had to put on those panels to get that to work. But it has a great effect. The panel on the left hand side of that, that is a pinboard is where that's an additional way of managing the space. We all know the benefits of having soft finishes in these areas to be able to help with sound reverberation. So it's not just the sliding doors. It's also the other fixed paneling around the systems that can help with duration.

Having said that, with our sliders, we can incorporate panels, where you have options for either whiteboards or pin boards to be incorporated. So that that can be an additional way of helping with that sound management. It also provides you with flexibility over privacy as well. So we can integrate. So on the left hand side there, that's a section through the middle of the door or module, a part of our door that has a pinboard in it. And it does create, you know a privacy strip and, and also the manifestation requirements for sliding doors and glass doors as well.

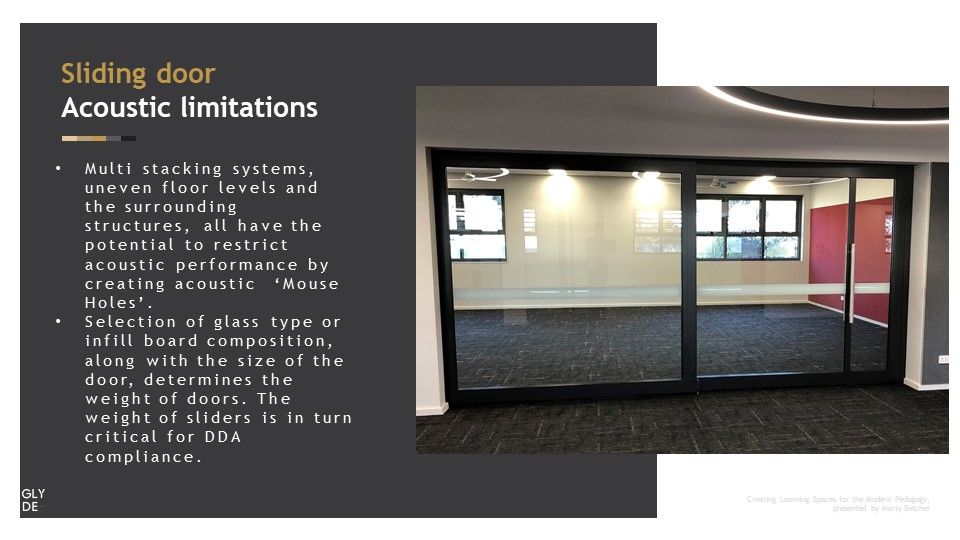

There are some acoustic limitations. As we would imagine with sliding doors I mentioned earlier that there has historically been a query over the performance of doors. Multiple reasons why that is the case why they are limited in their performance. When we have multi stacking doors such as the one we're looking at here, it's a dual slide on the overlap of doors does create weak points for acoustic performance. We try and manage that the best we can and acoustic testing shows us that when we incorporate to Rw 35 sliders for example, when they're in you know a dual configuration. Those sliders when tested are certified as an Rw 32 system. So you can see that there's a three Rw drop in performance when we incorporate different formats of sliders. The other things that can affect acoustic performance, just like all other building elements is the surrounding structure. Floor levels. You know, these, these openings are quite wide. So if there's ups and downs in the concrete or the substrate floor, then it can create mouseholes under these doors and therefore, limit the performance when they're installed on site. We try and interact with builders and get these as good as we can during the construction phase. But in some buildings, there are some limitations on what can and can't be achieved there so it's another limiting factor.

And then it's about the size of door and the type of glass that we can incorporate, whether it's glass or an infill panel. There are glazing codes that need to be adhered to. So for example, if we're incorporating, say, a sixmm glass into our panels, we know that we can only have a three meter square area of glazing without the need to be either an intermediate mullion or mid rail to reduce the overall size of the doors. The benefits of using a thinner glass are that we can create larger doors that are DDA compliant. Then we step up into thicker glass so we can achieve much larger glass areas in doors. But in turn, we need to be conscious that the doors are not getting too heavy for that compliance.

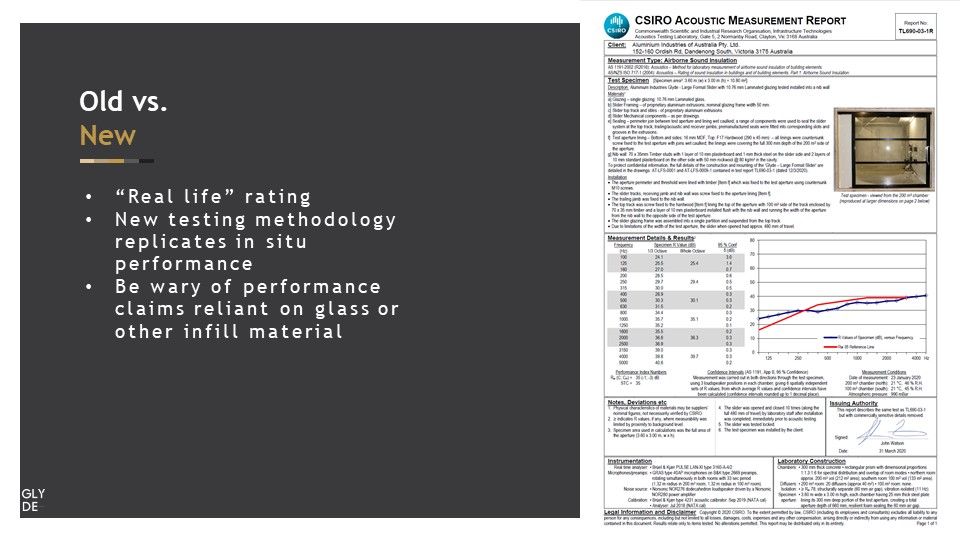

With acoustic testing and performance, we've got certification for doors and just be wary that when people are looking at all types of whether they be operable wall or acoustic sliding doors systems, that they ensure that the doors have been certified by a facility such as the CSIRO at Monash, where you'll get it after a product is tested.

A certificate comes out looking like this for those of you who may not ever have seen one. So I've just grabbed one of our certificates, and this is for our Rw 35 slider. So these are real world tests. And testing in, whether they be operable walls, or acoustic sliding doors, has become very stringent. So when we test these doors, they go into a lab, we have to step out of the lab, from after we have installed the doors, the CSIRO opens and closes these doors 10 times. And on the 10th time of closing, that's when they do their acoustic tests. So it's not like systems can be sealed up or, you know, any way of maniplulating installation to achieve a better rating. These are real world tests. So that's an important part. And we're not just claiming a performance of glass, for example, it's a full system certification.

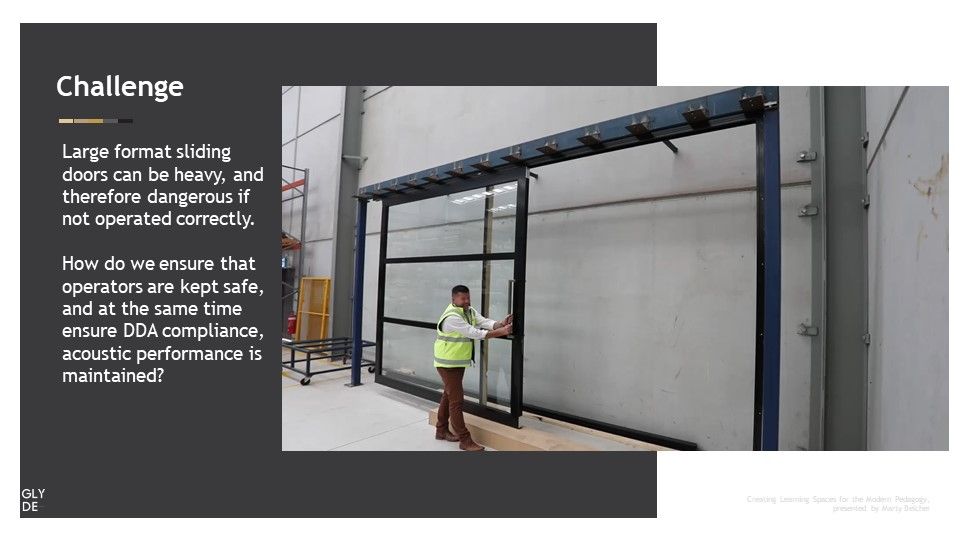

The last part is Safety. With large sliding doors, obviously, they can be quite heavy up to 200 kilograms, we can still make it a DDA compliant door.

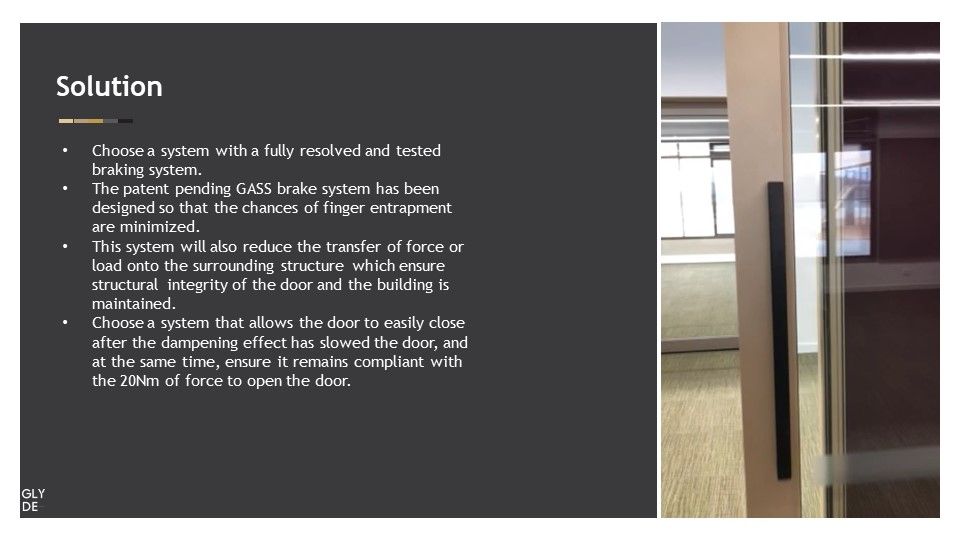

We need to ensure that there is safety systems that are built into these. I've just got this really quick video to show you. This is our test lab at our facility down in Melbourne and just play this video for you. So that's actually a 220 kilo acoustic slider. It's three meters tall and three meters wide. What we've done there is just illustrate that by incorporating a brake system. These large sliders even when they can get misused in some applications that they are still safe for the end operators. And that brake system that we've incorporated there does not affect the DDA compliance of that door at all.

I've got a second video here, I'll just play in a second. We have designed our own brake system called GASS. It's a Glyde Anti Slam System. And the benefits of this is that we're reducing the loads on the surrounding structure of the buildings that we're creating. So that when these large sliders do get closed, they're not going to do damage to any of the adjacent building areas. And then there also, most importantly, don't become a finger entrapment. So that door, I just gave her a fair shove. And as you can see, even if there were fingers accidentally left between the door and the receiving jam, the door does stop short of the jam so that doesn't become a fingering trap.

In summary, we've talked a little bit about creating adaptable and flexible spaces today, using large scale acoustic sliding doors. What we're trying to do with these particular products in our designs is promote health engagement well-being in our schools, be safe and inclusive, empower students, encourage intellectual engagement, and then make sure that they're fit for purpose. So the spaces in schools have multiple users, especially in government design schools, where they have multiple end user groups and our wider communities can use those spaces for multiple uses. And hopefully, we've gained a little bit of insight on how we can create some large spaces that are easy to reconfigure in schools today.

That is my quick presentation, thank you everyone.

Q&A

Q: Are those sliders double glazed with an air gap?

A: No sliders have a double-glazed system in them. All of our sliders are single glazed, so we rely on the acoustic performance of the glass itself to achieve the acoustic performance. Operable walls, however, do differ. They do come in in a double glaze system to achieve a much higher acoustic range.

Q: What is the thickness of the glazing?

A: So it does vary. Depending on the acoustic performance rating, either 6mm, so that's either 6.38mm or 6.76mm acoustic lam, and then it steps up to 10mm glass. So the 10mm toughened, enables us to have the handles fixed through the glass and inset or we incorporate a 10.76 acoustic lam to get the higher acoustic performance. So, Rw35, for example, uses a 10.76mm acoustic laminated glass.

For more information you can view their profile on Archify, visit their website or contact Marty Belcher - [email protected]

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia