Archify Live: How to Select the Correct Waterproofing for Your Projects

Archify Live is our web series that responds to an increasing demand for virtual learning and networking. Our latest session was held on the 10th of February 2022 and was presented by APTC. Below is a transcript of the presentation.

Waterproofing continues to be a misunderstood area of our industry and we really hope to shed some light on that subject today. We assume because you're on the call that you do have a keen desire to improve your waterproofing knowledge, and whatever level you feel comfortable with waterproofing, we aim to give you some key takeaways today that you can use immediately. We do feel qualified to talk on the subject.

By way of introduction, my name is Dave, this is Pete, and our company is APTC consultants. To give you a context, Pete, before his time with our company, spent over 25 years in the field, applying sheet membranes, project managing, working with builders directly, as well as working at the underlying engineering behind builds. Since then, he's worked with us for the last 10 years and has great success, selling directly into a very, very competitive market. We've written specifications and sold product directly to projects as diverse as grammar schools, sports centers, and even hospitals. We have the ability to write technical specifications specific to projects, provide technical assistance, and perhaps most importantly, give the right product for the right application, so we can definitely help.

Our outcomes for the presentation are, number one, to give you guys a better depth of knowledge, and to help clarify some elements of waterproofing that maybe are confusing. Certainly, to give you a good overview of our company, and how we can help.

Number two is to make the simple out of the complex. We pride ourselves on simplifying complex ideas, and presenting them to the market. Part of our brand is founded upon that and we also always say to ourselves internally that design is the key, every element of waterproofing, the engineering behind it, and every element comes together to form a simple concept that you and I can both understand. So thank you and welcome.

We'll begin with this. There was a real need for waterproofing within our industry and many people continue to be very much in the dark with how to achieve long term successful waterproofing solutions, and are now relying more and more upon the advice of waterproofing specialists and employing specialists in this area.

Now, why can we say that? The amount of waterproofing, callbacks, faults, unfortunately, rectifications over the last five to 10 years has really increased, and it's giving rise to a new culture where people are really looking to get waterproofing right from the beginning. They're not taking chances anymore, and they're employing the advice and counsel of experts and specialists in the field on this field, we certainly feel that we are a part of that. We do continue to receive many calls per week and per month asking for advice both for new builds, as well as, unfortunately, rectifications and we provide systems, products, and on the ground support for those inquiries.

There was a real change moving through our industry where people are taking a more disciplined approach at the beginning stages of a project and not leaving anything to chance as much anymore. We certainly feel that we've seen that and we continue to be a part of that growing, changing trend.

So here's an important point. There are key principles with regards to waterproofing that, when applied and implemented, will enable the success of waterproofing projects long term.

When applied correctly, the methods, methodologies, strategies and systems that we teach to the market have resulted in successful projects. There was a real peace of mind that comes with this as well. We've seen businesses and reputations grow and improve from the success of projects. Here are some of the key principles:

The product should be fit for purpose. There is no one product that fits all applications. Even though the datasheet might say it, in reality, they don't. The product should form part of a system. Primers reinforcements sealants don't mix and match and this is where you get into trouble and products start to fail. The waterproofing system should align with the engineering of your build and able to meet and exceed the length of the warranty. Most importantly, this relies on the substrate determinations, get all these right and everything will just flow on.

These methods are the backbone to any approach to waterproofing. If we follow these, it will meet all the warranties and exceed the expected timeframes. This should never be left to chance.

Further to that and expanding upon that concept and principle, here are some simple ways to think about waterproofing. We divided waterproofing up into either internal applications or external applications. Now, from there, we take it one step further and define the types of membrane: is it a sheet membrane or is it a liquid applied membrane? From there, with the external side of things we find out is it exposed or non-exposed type. One step further is it trafficable or non-trafficable. The beginning point is always “is it an internal application or an external application?”

Internal waterproofing is generally within the wet areas of the building: the bathrooms, laundries, toilets, and the like. It's generally either a one part or two part type liquid and 9 times out of 10 is a tiled finish. This is a waterproofing that we all probably are more comfortable and familiar with and it's an easier starting point. External waterproofing can involve everything from a roof terraces to balconies, podiums below ground applications as well. They tend to be a little bit more complex in terms of the product selection in the system. However, both sheet and liquid membranes do have their place here. We’d like to go through some picture examples now of these of these different types.

This is our internal membrane. Its SBR fibre reinforced with a light sand filling. The fibre reinforcement gives it that added strength even though it is a class three, and the added sand helps to key-in for the tiling and adhesive.

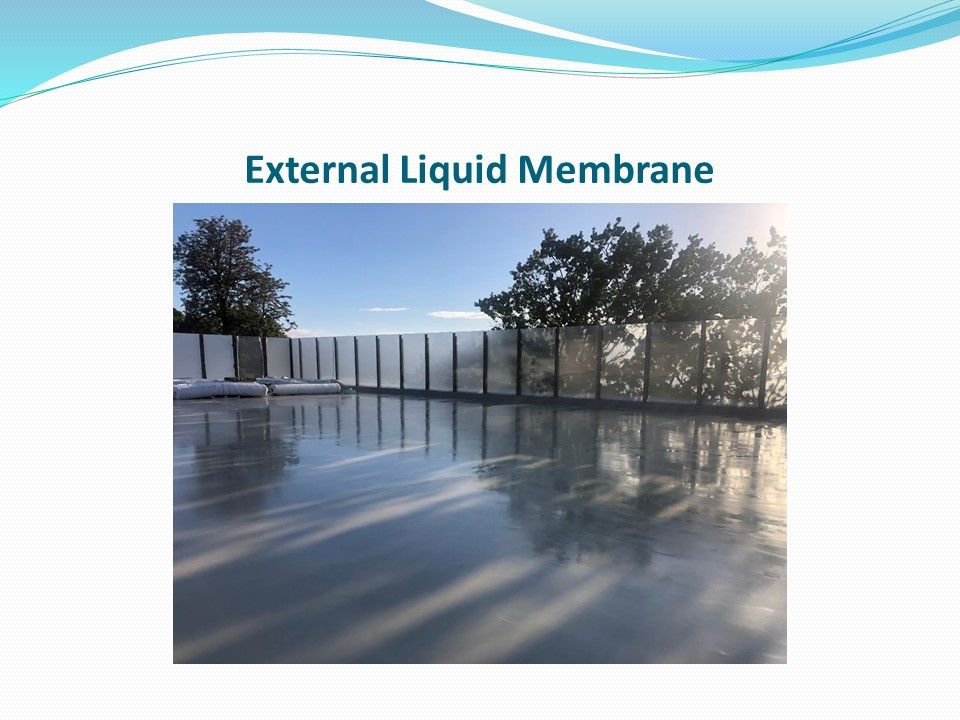

External liquid membrane - this is a Casali product, it's a self-levelling polyurethane. This was chosen to be used on a rooftop sports court project. It had to be flat and seamless due to a synthetic grass court that was going over the top as you can see by the rolls in the background. It’s quite a complex project where there's a two layer torch membrane under that wearing slab. Then the wearing slab was poured and then the self-levelling polyurethane was put over the top.

Membrane for lightweight like structure - a lot of domestic houses are built with lightweight, so the balconies are made of either ply or compressed fibre cement sheet. You get a lot of movement in the joints because everything's moving at all different rates. We recommend the Casali Self-stick Aderix for this application. This will get a screed-to-fall later on and then a liquid membrane for direct stick tiles we will put on afterwards.

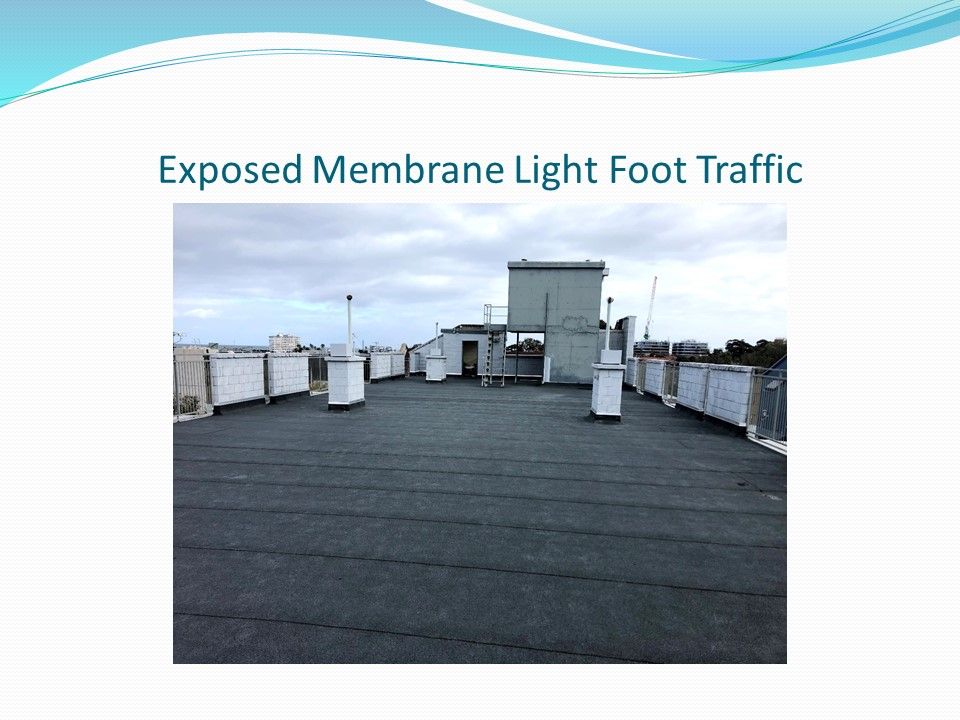

Exposed membrane with light foot traffic - This is a project where there was a failed, old membrane on the roof. We put forward this two layer, natural slate UV stable, mineral finished membrane. The job went really well and the finish speaks for itself.

Exposed special membrane - This is another reroof project in St Kilda, it's another two layer torch applied system but with a different finish. We went down the path of using a white mineral, as the units directly underneath were subject to getting quite warm in the summer months. We used a white mineral for the reflection to absorb less heat.

It helps to think about waterproofing by breaking it up into either internal applications or external applications, as well as defining it by the different types, whether they be sheet membrane, or liquid type membranes. The type of finish required in the areas of use will define what products of these that we choose for each, and we have pre designed systems for each. This is an important subject, a company like ours is very much is founded upon both the quality of the relationships that it has with suppliers, as well as the quality of the products that it brings to market.

We’re fortunate enough to have a high quality relationships and high quality products and we have relationships with suppliers, both the national and international level. One of our key waterproofing relationship is with a company called Casali. Being with Casali enables us to offer some of the highest quality sheet membranes available in the market, as well as gives us access to liquid membranes and primers and liquid systems, the likes of which aren't available anywhere else in Australia. Along with their waterproofing systems and waterproofing division, Casali also has a sports surfaces division. Within that, there’s components of acrylic surfaces, rubberized surfaces and polyurethane surfaces. We want to take in now some examples of that.

As Dave touched on earlier, these are some of the special membranes that Casali manufacture, and one of them is their higher class Dermabit range. This is Casali Dermabit membrane it's a single layered glue applied system on a wearing slab on a hollow core panel. The reason this system was chosen was speed of application and the movement that was going to occur on that wearing side because it's on a hollow core panel.

The Casali Acryroof plus system - This is another unique system to Casali, it’s a fully reinforced, highly UV stable acrylic system. It also can have a non-slip acrylic topcoat put over the top. This is used in another data center where the client didn't want to sheet membrane, they wanted a seamless membrane system. But, we couldn't put just a single part liquid unreinforced on this, as the wiring side was cracked very badly. We had to fully reinforce it to take up those cracks, so the membrane wouldn't open up at a later date.

Casali’s green roof system - This is a two layer torch-supplied system for green roofs, planter boxes and anywhere any vegetation is going to be put. The top layer, as you can see on the right, has the anti-root inhibitor in it so, if the roots do come in contact with that membrane, they will not proceed any further.

By just a quick shot of the full range of Casalis, David touched on the Sport Surfaces division, it forms part of the Casali portfolio. These sports surface systems complement what Casali manufacture. And as you can see, the colours are very vibrant. This was done this is a four or five court system, liquid rubber done for private school out in Cranbourne.

Having relationships with international suppliers like Casali enables us to offer waterproofing to really all sectors of the market and gives us an entry and a foot-in to the world of sports. Working with Casali and their divisions and their portfolio is something that we continue to be really excited about.

We want to share this. We offer very much a hands on approach with waterproofing within the market. We offer detailed specifications and, very importantly, site inspections to review waterproofing applications and this helps ensure a quality assurance throughout the project. Many kinds of customers purchase from us because they feel that they will receive the technical backup that they need through their projects. It gives them confidence, it gives us confidence, and it builds fantastic relationships as well. Sometimes we offer the inspections before, during and even after the installation. That's pretty comprehensive and it's a big part of what we offer as a company as well to.

Furthermore, we take a lot of pride in what we do and what we specify, we follow it to the nth degree. On the back of that, to form part of the warranty we provide, we engage an independent company called ILD Australia. ILD Australia test the water tightness of waterproof membrane and will come in after the membrane has been installed. I do my inspections and then they'll come in and probe every lap, seam, joint and electronically test to find a breach. If there is a breach, it is no good. The contractor will come back and repair that, it will get retested and rechecked to sustain it as one complete watertight system.

Following on from that we implemented a real time QA monitoring system. We've got another third party in called Conqa who created an app for us, and that app is site specific to any installation. Come time to specification in the areas involved in the membrane that's involved, I set up a complete QA system from start to finish step by step. the builder, the contractor, the client are all in on the app. it's real time QA, moisture testing is conducted, photos taken, photos uploaded, primer, first layer, second layer, and so on and so on. At the end of the project that can either be downloaded as a PDF, or remain in the ether to get back to later at a later date. All these forms part of the whole approach to what APTC has to offer. The hands on assistance, side inspection, independent testing and real time QA monitoring.

The collaborative approach with our clients does give us a competitive edge in the market and it's something that they enjoy very much and rely upon, and is available to professionals and subcontractors at all levels of the market. Before we wrap up we'll go through what we covered today.

So number one, we discussed that the market has a real need for waterproofing expertise and consultations. There’s a real change moving through the industry where people now are really relying upon the advice and counsel of experts in the field and, essentially, not leaving that element to chance anymore. The industry has become too complex, there's too many integrated elements and it's really paving the way for a new and new era that we certainly feel that we're very much a part of.

Number two, we've said that there are key principles that make waterproofing work long term, that these are learnable, and as well, they are also repeatable. That can't be left to chance, doesn't need to be left to chance, it’s a big part of our business and its growth is the education of these principles and implementation of them.

Number three, we've taken the time to separate waterproofing into two areas: internal applications and external applications. We further separated them into either sheet membrane, or liquid type membranes, and volunteer we have pre designed systems for each and, again, they are also learnable.

Before we showcased our relationship with Italian based supplier Casali, we’ve shown some of their product portfolio, some unique products that are doing really well in the market and have a real place here. We also touched on that the fact that they have a sports division, which is a part of our portfolio as well, although not part specifically of this talk today.

Finally, number five, we've gone into a little bit about our Q&A procedure, and how our site inspections and collaborative approach with our clients has enabled their businesses to grow, our businesses to grow and is a big part of our business model.

We want to thank you all for taking the time out of your busy day to be on this chat. We've had a good time and we encourage you to reach out either myself or Pete, personally, and we'll be sure to reach out with you in the coming weeks and months as well. Thank you very much.

Q & A:

Q: Do you prepare SP 1.4 performance based solution as required by the NCC to obtain a building permit?

A: That’s a good question. All products comply with the National Construction Code. So a performance solution is pretty much done by another specialist company, if it's outside of the parameters, other construction codes.

Q: Have you found you're having issues with supply in the COVID Era?

A: That's a greater question. And the answer that is no. Yes, Raw materials, minerals and all that. No, manufacturing of the product is still going forward. We haven't had no delays in that. There's a minor delay with shipping, everyone’s having that at the minute. But we just allow for that on our ordering and fingers, crossed up to date, we have not run out of any material, which is fantastic.

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia