It's Time We Manage Our Waste Better

Cover image source: Washington State Department of Transportation

As lay people, we all understand the basic principles of recycling: objects and materials that are no longer fit for their intended use are repurposed for other means. But are we just delaying the inevitable? Some argue that instead of recycling materials to create inferior products, our efforts should be focused on developing materials that remain useful for longer. However, when it comes to the demolition of buildings, waste is almost inevitable This article will discuss how different building materials are handled during C&D and the various methods used to recycle them.

Waste generated by C&D

When it comes to construction, a large of amount of waste is already being generated at the site before there’s even a chance for maintenance, renovation or demolition. The most common waste you’ll see at any construction site are concrete, wood, drywall, asphalt, metal and cardboard, which make up 70-95% of discarded waste at commercial or residential sites.

This figure hasn’t been improving lately either, according to a report conducted by Department of the Environment and Energy in 2018, construction and demolition waste materials increased 2% over 11 years. But what causes all this construction waste?

If you’ve worked in the design or construction industry, you might already be aware of some of the leading causes of waste on site; excess packaging, offcuts from materials, weather-damaged goods or other external influences. Occasionally, these are a result of human error or mistakes, such as poor management or wrongly specified products. However, the biggest cause of construction waste, according to multiple studies, is changes in design.

Despite our best efforts to minimise waste through design, changes in design of a building during construction is another major source of waste generation. This is a very frustrating statistic, as this can largely be mitigated with good communication between client, architect, supplier and contractor. But, as many of us know, it’s sometimes difficult getting everybody to work together. It is abundantly clear that effective communication DOES reduce waste, but its waste that shouldn’t be there in the first place. However, only around 10-30% of all C&D waste is from the construction side. The rest is made up of debris from demolition being incorrectly recycled or sent straight to landfill

When waste happens, what can you do about it? Many companies already have strong recycling policies onsite, for example CPB Contractors have initiatives to use recycled materials over raw, and to recycle any on-site waste they can. Here are the most used methods of recycling for some common building materials.

Concrete & Cement

Concrete is crushed and foreign objects are removed to prepare for recycling. Shutterstock.

Concrete waste in Australia makes up approximately 82% of all waste, and of that around 54% is already recycled. One of the differences between recycling concrete and other materials is that there is often a fair amount of foreign chemicals and materials in concrete, making the extraction of useful materials difficult. However, since concrete makes up such a large portion of C&D waste overall, it is essential that effort be made to reduce the impact. Usually concrete is recycled into…you guessed it, concrete. This involves breaking down the concrete into pieces and removing any foreign materials. We have recycled concrete since WW2, when Europe needed to hastily remove debris from war torn areas while simultaneously rebuilding structures. Although recycled concrete aggregate isn’t as strong natural aggregate, it still can be used as structural cement.

Wood & Timber

Pallets are one of the main offenders when it comes to timber waste, due to it's low quality. Shutterstock.

Coming in closely behind concrete in biggest construction waste offenders is timber and wood. Not only are they one of the biggest landfill contributors, but recycling rates for timber are much lower than concrete and steel. Most of this wood comes from pallets, which are quite low quality and are usually only suitable for mulch or burning. According to a UK study, only 10% of pallets actually got reused. Targeted demolition can help increase the amount of wood and timber reclaimed from C&D sites, which is currently only about 10% to 20%. In fact, taking care with demolition and extracting valuable timber can actually help reduce the cost of a project, as several companies have discovered and are now profiting from. Valuable wood that can be repurposed is often lost to landfill. Native timber used in buildings and furniture can last up to 90 years!

Metal and Steel

A giant magnet separates iron from other metals at a processing centre. Shutterstock.

Introducing the heavyweight champion of recycling (no pun intended), metal! Steel is 100% recycled and the most recycled building material on the planet. Up to 98% of steel in demolished buildings is recycled already, and many of our steel products are made up of half recycled materials! Unlike wood and concrete, steel can be recycled very easily into an identical product and doesn’t need to be ‘downcycled’ into inferior products. There has also been a concerted effort to reduce the embodied carbon and water required to manufacture and recycle steel, although the average carbon emissions of 1.85 tons per ton of steel in 2018 means we have long way to go for complete carbon neutrality.

Plastic

Recycling plastic is a necessary but time-consuming and labour-intensive process. Shutterstock.

The scourge of the environment is finding a new home in the construction industry. As most of us know, plastics last thousands of years and are mostly used for single used packaging. Traditionally in construction, plastic is used to create durable replacements for other materials, such as acrylic windows, polycarbonate facades and polyvinyl flooring. These products are highly durable, and can list as long as the life of the building. It is also a myth that most plastics can’t be recycled; in fact, they can be by shredding and melting down just like metal. Although this results in the molecular structure of the plastic deteriorating, it can be improved again with chemical additives. There are innovators in the field that are working with different plastic mixtures to create materials like bricks out of recycled plastic, however plastic is recycled less than other materials because it is an inconvenient and unprofitable process. Hopefully this changes, or more incentives are created to encourage industries to start recycling plastic.

What construction materials can I recycle?

Pretty much all of them, except hazardous and toxic materials. Steel is the most recyclable material, while timber, cement and plastic construction materials are more likely to end up in landfill.

Why should I recycle construction materials?

Humans produce just over 2 billion tonnes of waste annually, and almost a third is dumped openly. However, there is not a one-size-fits-all solution. Waste management and recycling needs to happen at a local level, with every industry and governing body across all sectors doing their part.

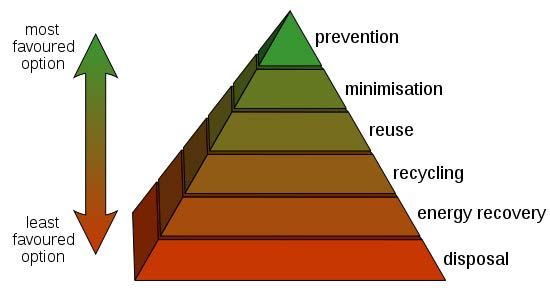

What is the Waste Recovery Pyramid?

The waste recovery pyramid. Source: Wikipedia Commons

The Waste Recovery Pyramid is a diagram describing the most efficient way to manage waste. At the top is the most important step; to avoid or to reduce waste altogether. This step is about trying to reduce the overall materials used in production. The next is to reuse without any extra processing. Not only is waste from processing avoided at this stage, recovering materials without processing makes them highly economically productive. Next is recycling, and below that is energy recovery. Energy recovery occurs when other reuse options aren’t practical, but recovering some utility from it is still possible. Last is treatment and disposal, which is the case for hazardous materials that can’t be reused.

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia