Waste Watchers: Converting Waste Into Building Materials

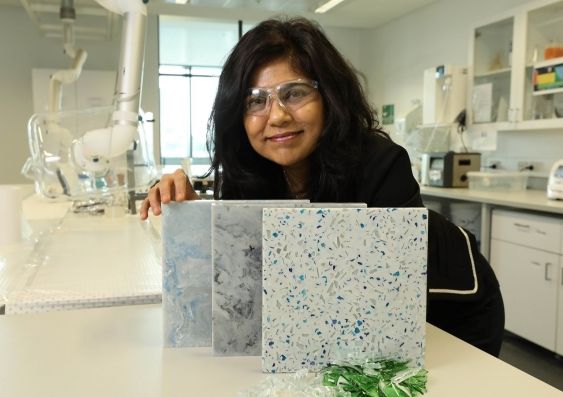

The University of NSW’s Centre for Sustainable Materials Research and Technology (SMaRT) is turning waste into building materials in response to Australia’s growing waste crisis.

In 2018-19 Australia generated an estimated 75.8 million tonnes of waste, according to the Australian Bureau of Statistics. Until recently, a colossal amount of that waste was exported to overseas trading partners, particularly to Asia. China’s recent ban on the import of several types of solid waste, coupled with Australia’s new legislation banning the export of unprocessed waste overseas, has led to an increase in stockpiling and landfilling of glass, plastic and textiles, to name a few.

It is estimated that by 2050, global waste growth will outpace population growth and there will be more plastic in the ocean than fish.

It is more important than ever to find sustainable waste management solutions, and Professor Veena Sahajwalla, director of UNSW’s SMaRT Centre, is breaking new ground with green manufacturing technology. Professor Veena Sahajwalla is an internationally recognised materials scientist, engineer and inventor, revolutionising recycling science. Her cutting-edge green manufacturing technology is transforming many types of waste, including glass, plastic, textiles and wood, into valuable building materials and products. These include:

ENGINEERED STONE: UNSW's modular factories grind glass waste and re-form it into engineered stone which mimics a wide variety of natural and engineered stones available on the market. It is suitable for domestic and commercial projects, including kitchen bench-tops, bathroom tiles and stone slabs used in building foyers.

FLAT PANELS: Textile waste is shredded, chemically treated and compressed under heat to form solid panels. The panels have proven to be strong, flexible and fire and water resistant in test conditions, making them suitable for use as floor tiles, wall panels or other interior finishes. Depending on the blend of components, the panels have different textures and colours resulting in a product that resembles wood, ceramic or stone.

MANUFACTURED TIMBER: Timber waste is combined with a range of mineral inputs to produce a sustainable, UV and water-resistant, and fire-retardant particleboard. This innovative product can be used in anything from reusable transport pallets to internal and external building cladding.

Image courtesy of University of New South Wales

UNSW’s SMaRT Centre is revolutionising the way we address waste management in Australia. Their innovative green manufacturing technology offers an effective solution for reducing waste and a viable alternative to unsustainable exporting, stockpiling and landfill problems.

When selecting materials for your next project, perhaps consider specifying green materials and recycled products and become part of the solution to one of the greatest environmental challenges of our time.

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia