Barrier-Free, Freestanding Drench Showers

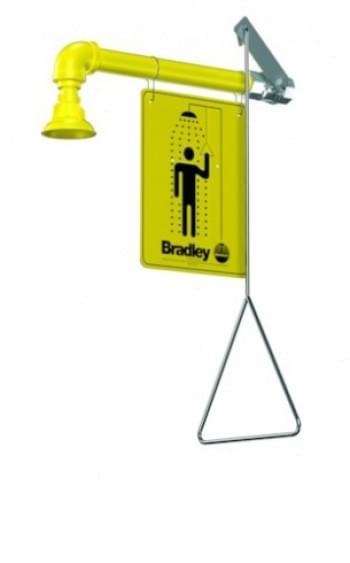

When there’s the possibility of full-body chemical contamination, the first choice is an ANSI-compliant, full-body drench shower. Bradley drench showers, the S19-110 line of products, are a great choice when a wall-mounted drench shower isn’t practical. And with the BradTect® corrosion-resistant yellow coating standard on most units, these drench showers are not only easy to see, but durable enough for your tough work environment.

Key Features

• SpinTec showerhead improves water distribution

• Exceeds ANSI minimum water flow of 20 GPM (76 L/Min) at 30 psi (207 kPa)

• Stay-open ball valve with single-step activation

• Triangular stainless steel pull rod

• Universal ID sign

• BradTect corrosion-resistant yellow coating (except on stainless steel, PVC

and chrome models)

• 1¼" (32 mm) NPT inlet

• One-year warranty

• Top- or mid-level supply standard on all drench showers and combination units

• ANSI/ISEA Z358.1 certified models available

• AS/NZS4775:2007 & AS4020 certified models available

Emergency Fixture Facts

Drench showers are required to have 16" (406 mm) of clearance around the fixture,

from the center of the spray pattern. ANSI /ISEA Z358.1 Section 4.1.4

Barrier-Free, Freestanding Drench Showers

When there’s the possibility of full-body chemical contamination, the first choice is an ANSI-compliant, full-body drench shower. Bradley drench showers, the S19-110 line of products, are a great choice when a wall-mounted drench shower isn’t practical. And with the BradTect® corrosion-resistant yellow coating standard on most units, these drench showers are not only easy to see, but durable enough for your tough work environment.

Key Features

• SpinTec showerhead improves water distribution

• Exceeds ANSI minimum water flow of 20 GPM (76 L/Min) at 30 psi (207 kPa)

• Stay-open ball valve with single-step activation

• Triangular stainless steel pull rod

• Universal ID sign

• BradTect corrosion-resistant yellow coating (except on stainless steel, PVC

and chrome models)

• 1¼" (32 mm) NPT inlet

• One-year warranty

• Top- or mid-level supply standard on all drench showers and combination units

• ANSI/ISEA Z358.1 certified models available

• AS/NZS4775:2007 & AS4020 certified models available

Emergency Fixture Facts

Drench showers are required to have 16" (406 mm) of clearance around the fixture,

from the center of the spray pattern. ANSI /ISEA Z358.1 Section 4.1.4

Barrier-Free, Freestanding Drench Showers

When there’s the possibility of full-body chemical contamination, the first choice is an ANSI-compliant, full-body drench shower. Bradley drench showers, the S19-110 line of products, are a great choice when a wall-mounted drench shower isn’t practical. And with the BradTect® corrosion-resistant yellow coating standard on most units, these drench showers are not only easy to see, but durable enough for your tough work environment.

Key Features

• SpinTec showerhead improves water distribution

• Exceeds ANSI minimum water flow of 20 GPM (76 L/Min) at 30 psi (207 kPa)

• Stay-open ball valve with single-step activation

• Triangular stainless steel pull rod

• Universal ID sign

• BradTect corrosion-resistant yellow coating (except on stainless steel, PVC

and chrome models)

• 1¼" (32 mm) NPT inlet

• One-year warranty

• Top- or mid-level supply standard on all drench showers and combination units

• ANSI/ISEA Z358.1 certified models available

• AS/NZS4775:2007 & AS4020 certified models available

Emergency Fixture Facts

Drench showers are required to have 16" (406 mm) of clearance around the fixture,

from the center of the spray pattern. ANSI /ISEA Z358.1 Section 4.1.4

Australia