-

Australia

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

The NCC 2022 Volumes 1 and 2 Performance Requirements F8P1 and H4P7 for Class 1, 2 and 4 states “Risks associated with water vapour and condensation must be managed to minimize their impact on the health of occupants.”

As far as the insurance industry is concerned, a leaking wall and/or mould mildew are defects and are not covered by most of the building and PI insurance policies. The NCC 2022 requirements F8P1 and H4P7 for Class 1, 2 and 4 buildings have been mandatory since 1st October 2023. Thus, non-compliance with these NCC requirements is now recognised as a clear building defect and, going forward, will clearly be a point of liability and potentially subject to legal suits.

The designer (architect , engineer, specialist waterproofing advisers including BCA Consultants) will be individually responsible according to latest acts introduced in various Australian states for all their design input to a project . The building defects relevant to water/water vapour leak, mould/mildew are not covered by the designer’s PI insurance . Therefore realistically building designer can only protect herself/himself by specifying “ Full Tanking System” (i.e. British Standard BS 8102:2022 – Type A Barrier , refer for further information https://www.dincel.com.au/theme_dincel/static/resources/compliance/australian-waterproof-basement-construction.pdf) since there is no better methodology to avoid this liability . The designer who specifies full tanking system passes the responsibility to the builders and relevant trades.

Please read below to understand this potential liability problem ;

The NCC refers to “Risks associated with water vapour and condensation…...” To avoid mould/mildew, the causes must be eliminated. There are two primary sources of water and/or water vapour in a structure: (a) Condensation: Various sources (and academic papers) note that a relative humidity of 60% or greater will provide a condensation water source. So, the humidity level within the interior space and/or the temperature at the internal face of an external wall must be controlled. (b) Leaking external wall: A leaking external wall (basement and façade walls) will result in significantly more water presence than what will occur through a condensation water source, hence all but guaranteeing mould/mildew development.

Research suggests that mould and mildew is much more prevalent than was first thought (click on the following link (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4772214/). The Australian Government is so concerned about the issue that they commissioned a Parliamentary Committee to investigate the issue. One of the key recommendations of the Final Report (Oct. 2018) was to investigate the adequacy of building codes in relation to mould/mildew. No doubt a precursor to recent changes to the NCC.

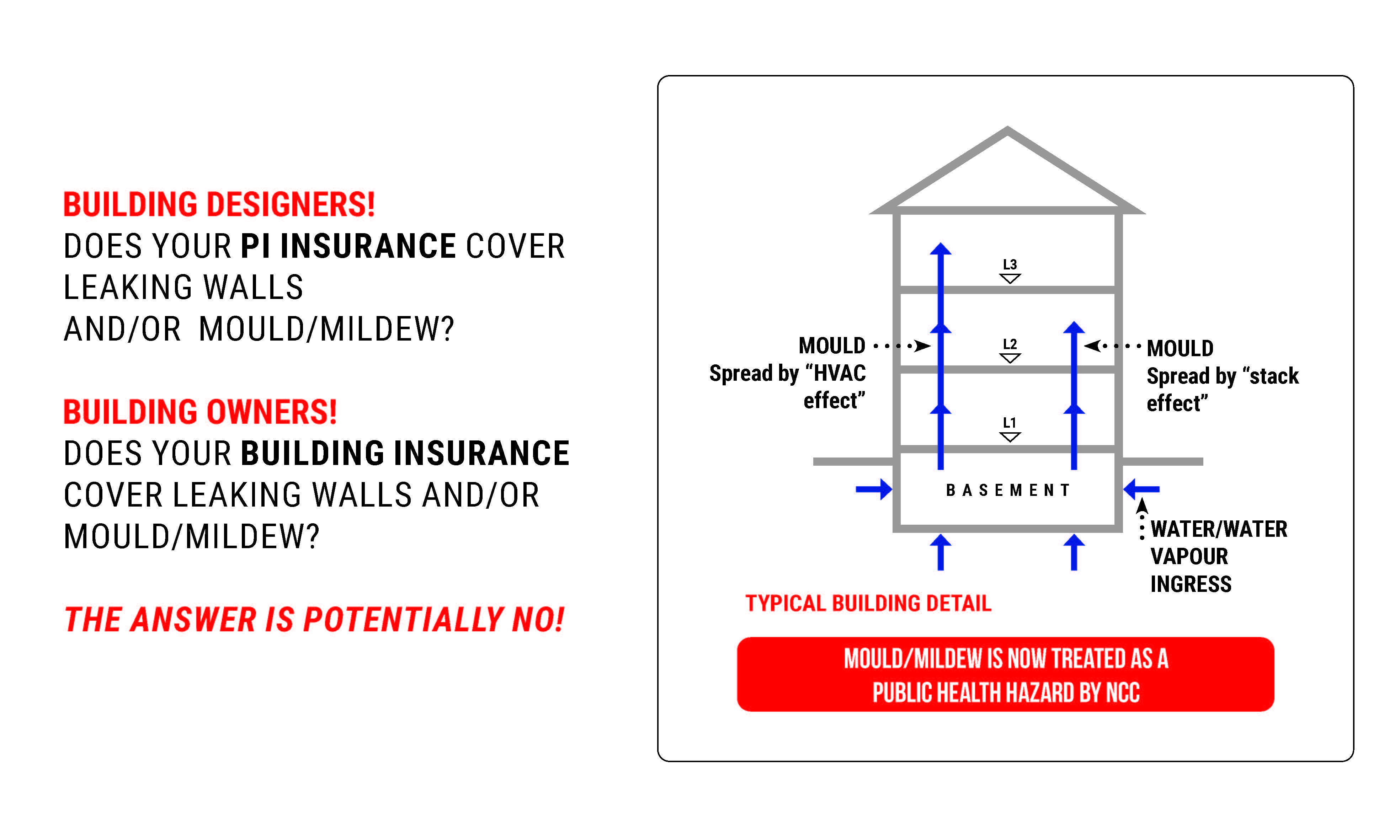

Basements relying on the ongoing pump-out drainage system during the life of the structure would have wet walls which will also potentially cause mould/mildew. Research by the Universities of Yale and Tulsa (https://pubs.acs.org/doi/10.1021/acs.estlett.9b00214) into mould transmission in a 3-storey building with a single level basement found that up to 30% of the basement mould/mildew travelled to the 2nd floor as shown in the above diagram. The commentary for this report suggests that mould transmission would be more than 30% for a property with a HVAC System.

A building owner will now be able to a make claim against building designer, certifier (private or local Councils) and/or builder for building works displaying building defects in the form of leaking walls and/ or mould/mildew. Such claims will create significant problems as leaking walls and/or mould/mildew are not generally covered by the insurance industry. Lawyers acting on behalf of a building owner may pursue legal action against all parties associated with the defective works. The only solution to avoid such defect/s in and emanating from the basement would be for the building designer to specify a full tanked system. A full tanked system can only be reliably achieved by bonding membranes directly onto the imperfection free face of the full height structural basement walls (not onto rock face or face of shotcrete applied onto shoring) or alternatively, by utilising the fully tanked and warranted system offered by DINCEL, found at https://www.dincel.com.au/products/waterproof_warranty.

An important issue to understand is that, no matter what system is installed, the unexpected can occur and wall, footing slab-wall junction can leak during the life of the structure. The critical issue in such cases is to identify the specific source of the leak and repair it. With a conventional full tanking system (membrane is bonded to conventional structural wall) it is exceedingly difficult to identify the point of leakage and to rectify the problem without interference with the structure and without causing inconvenience to building occupants.

You will find that DINCEL solution is superior to any other fully tanked system when considering cost, construction time, rectification work (if required at all) and the system comes with up to 50 years comprehensive Warranty (incorporating material and workmanship) against leakage.

Contact Dincel and let us take the liability away from you.