-

Australia

Copyright © 2026 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

18 Nov 2021 by Enware

Accidents in the workplace happen. Ignorance about safety in the workplace, however, is inexcusable. In Australia, the sixth leading cause of workplace injury is from burns, with 2,490 claims made per year1. Of this, 935 comprise chemical burns and other hazardous substances2.

Chemical burns account for 30 per cent of burns-associated death, and can be associated with significant physical, psychological, social and economic burden3. For those injured, the recovery can be painful and costly, with implications not only for the individual but for their family, their colleagues and even the community at large.

In the modern Australian working context, there are stringent safety codes set by law for those working with hazardous substances. These regulations ensure that lawful practices are maintained and that the correct equipment and information is accessible to those working with dangerous goods and substances.

The question for managers to consider though is one about minimising risk. Besides adhering to the regulations, what actions can an employer take to minimise the risk of employees working with hazardous substances?

This white paper tackles this question, with a discussion of relevant Australian standards, safety systems and equipment that can minimise the impact of workplace accidents. It also provides examples and context to injury from people working with hazardous substances, with the aim to provide readers with a clear insight into good practice.

By definition, hazardous substances include those that a pose significant risk to health and safety if not managed correctly. For example: toxic chemicals, chemicals that cause skin damage and carcinogens4.

There are a number of environments where workers may be in contact with hazardous substances. Manufacturing plants may either produce hazardous substances or use these in their production

processes. Those working in the aviation sector need to be mindful of aviation fuel, which is extremely hazardous. Likewise, those transporting or storing dangerous goods have to ensure there are measures in place to protect employees.

Even in environments that are not considered high-risk, such as schools and universities, hazardous chemicals will be found in laboratories where students conduct scientific experiments. Or public swimming pools, where chlorine is used. Additionally, hospitals and medical clinics regularly use medications that are considered highly toxic. It is important that all of these contexts are considered in discussions about hazardous chemicals and workplace safety.

In a mining context, hazardous chemicals are typically found in process plants and refineries. These often include acids such as sulphuric acid, hydrochloric acid and nitric acid, which are frequently used to dissolve metals in ores.

Moreover, many mines have reverse osmosis or other water treatment plants and hazardous chemicals include acids and chlorine. Common hazardous chemicals are also used in gold processing such as acids, cyanide and fluxes. Ammonia from electrowinning and lead, arsenic or mercury from smelting gravity gold may need to be managed at mine sites as well5.

All Australian employers have a duty of care to their employees to ensure their health and safety as is “reasonably practicable” under the Work Health and Safety Act. ‘Reasonably practicable’ duties in this legislation include: taking into account the likelihood of the hazard or risk involved; the degree of harm that may result from the hazard or the risk; the knowledge of employees about the hazard or the risk; the availability and suitability of ways to eliminate or minimize the risk; and the costs associated with reducing or removing the risk (this must take into account whether the cost to eliminate or minimize the risk is grossly disproportionate to the risk itself)6.

As a result of this legislation, the Workplace Health and Safety (WHS) regulations stipulate certain conditions employers must abide by when it comes to hazardous substances. One of these conditions is that all hazardous chemicals are to be correctly classified. Other key stipulations are that hazardous chemicals are labelled and safety data sheets are supplied and made available to those working with hazardous chemicals7.

There are a series of Australian codes of practice relating to the management of hazardous substances as well as guidance notes on how to identify risks. In situations where a risk cannot be eliminated, control measures must be implemented8.

WHS Regulations: Using, handling, generating and storing hazardous chemicals in the workplace

Employers must:

Source: Safework Australia, WHS guidelines: https://www.safeworkaustralia.gov.au/doc/model-work-health-and-safety-regulations

One of the most common measures adopted in the workplace to minimise the impact of injury from hazardous substances include the installation of emergency eyewash and showers. While the first aid response for each

hazardous substance will be different – as the relevant Safety Data Sheets (SDS) determines this – many require immediate flushing or a rinsing of the affected area.

Speed is essential in a first aid response to a hazardous substance injury. Delaying treatment, even for a few seconds, may cause serious and permanent injury. In Australia, many of the SDS cite a requirement for emergency shower and eyewash systems to be in place as a first aid response.

For example, the SDS for sulphuric acid instructs that victims of eye contact with the substance should wash and rinse the eye area with large amounts of water for at least 15 minutes. Likewise, those who have had skin contact with the acid are instructed to immediately drench with running water, remove clothing and then continue to wash the skin and hair with plenty of water until advised by the Poisons Information Centre9.

In response to industry requests for a standard that covers emergency eyewash and showers equipment, the Standards Committee Australia created the AS 4775. This Standard specifies minimum performance and use requirements for eyewash and shower equipment for the emergency treatment of the eyes or body of a person who has been exposed to materials that may cause injuries10.

" While it is encouraging to see that the number of workplace fatalities has significantly decreased over the last few decades in Australia14, the need for emergency shower and eyewash equipment as well as awareness, is still vitally important.

What the WHS cannot cover in their regulations and guidelines is the unique context of any given workplace. While it is important to be compliant and ensure all the necessary WHS requirements are met, communication with employees about the risks and policies regarding hazardous substance is recommended. This empowers managers to ask the right questions about the working environment and ensure they are implementing the most suitable – as well as compliant – control measures and installing this equipment in the most practical of locations.

The first seconds following an eye injury or skin burn are often critical to minimising the impact of the injury. The AS 4775 dictates that both emergency eyewash and shower equipment is available for immediate use. The Standard specifically states that it “shall take no longer than 10 seconds for an individual to reach the nearest facility”11.

Regarding personal eyewash units, the Standard says that they may be in the immediate vicinity of employees working in a potentially hazardous area as their main purpose is to supply immediate flushing fluid. The Standard states, “with this accomplished, the injured individual should then proceed to a plumbed or self-contained eyewash and flush the eyes for the required 15-minute period”12.

Employers also need to take into account other factors regarding the location. These include workplace lighting, obstructions to the path of travel and the work environment. The Standard notes that: “some situations may warrant the placement of equipment significantly closer to the hazard.” It uses the examples of highly corrosive chemicals and exposure to strong acids or alkalis as situations where distance should be considered based on advice from “appropriate consultants”13.

While it is encouraging to see that the number of workplace fatalities has significantly decreased over the last few decades in Australia14, the need for emergency shower and eyewash equipment as well as awareness, is still vitally important. This fact is best illustrated by real examples.

Freak liquid zinc accident in Adelaide factory

In December 2017, three workers in an Adelaide factory were splashed with 450-degree liquid zinc after a beam fell into the metal. The event was labelled a “freak accident” by those working at the site. Fortunately, quick-thinking colleagues managed to get each of the men under emergency showers and eyewash stations – including one who was taken to hospital afterwards for serious facial burns15.

Chemical tank burst in Melbourne’s west

In early 2016, two factory workers in Melbourne’s west were sprayed with burning acid after a 1000-litre chemical tank burst. One of the employees was covered with acid on his face, neck, chest and arms during the industrial incident. An ambulance spokesman said that because he managed to rinse the burns quickly, his chances of recovering with minimal damage were much improved16.

Zinc smelter explosion

A 34 year-old man was seriously injured at the Nyrstar Hobart zinc smelter in July, 2017, after an incident in the electrolysis department. Police described the incident as a possible “spontaneous explosion”. This is still undergoing investigation by Worksafe Tasmania as to whether the company need to change their safety processes and emergency response17.

It is unsettling enough to acknowledge that accidents can and do occur with hazardous substances – but to have substandard emergency equipment or no equipment in place at all – is inexcusable. One of the best ways to ensure that you have reliable and compliant emergency eye/face wash and shower equipment in place, is to choose a brand that has demonstrated its effectiveness in the Australian market.

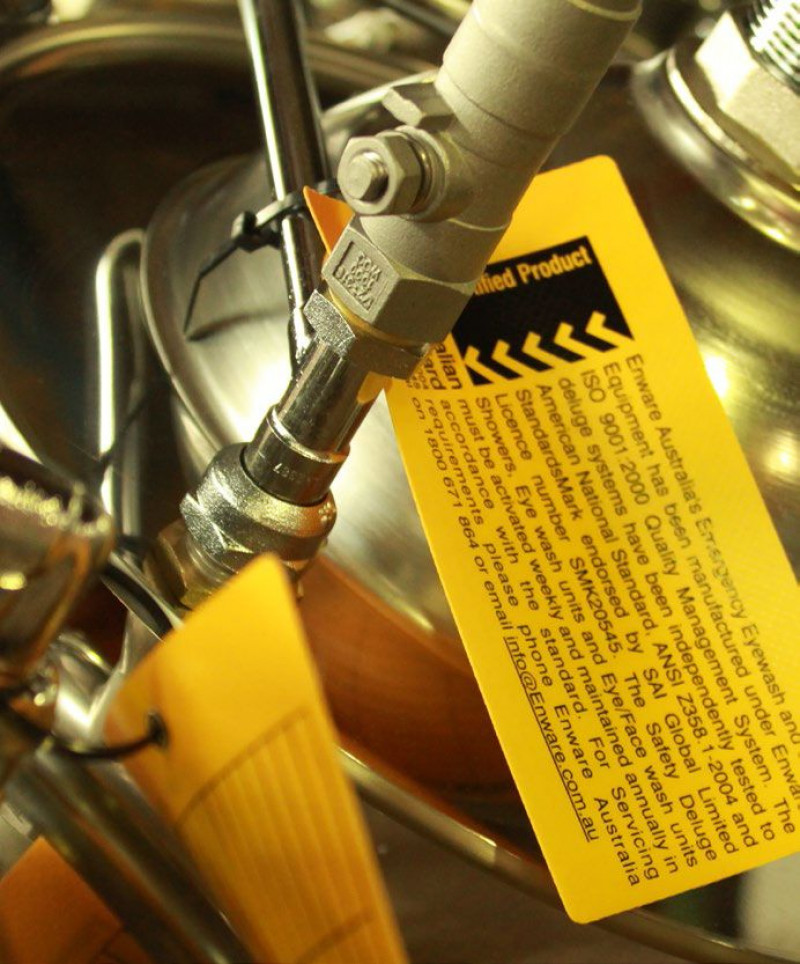

Enware is an established Australian manufacturer of emergency safety showers, eyewashes and decontamination equipment. They have been supplying trusted, leading safety systems for 30 years. Their emergency showers and eyewashes are independently certified and meet the criteria of both the Australian standard AS 4775 as well as American Standard ANSI Z 358.1.

Having reliable safety systems in place helps safeguard the wellbeing of your employees. When working with hazardous substances, employees deserve the best first response system. Enware’s proven experience and knowledge with emergency showers and eyewashes along with their expertise in the design and manufacture of compliant safety systems goes a long way in bringing peace of mind to your employees in the event of an emergency.

For more information, visit: www.enware.com.au

1. Australian Workers’ Compensation Statistics, 2013-2014

2. Safe Work Australia Statistics, 2014-2015

3. Cutaneous chemical burns: assessment and early management, Volume 44, No.3, 2015, Australian Family Physician, Royal College of Australian General Practitioners

4. Safe Work Australia, Hazardous Chemicals Overview: https://www.safeworkaustralia.gov.au/chemicals#overview

5. Guidance about hazardous chemicals, Government of Western Australia, Department of Mines, Industry Regulation and Safety ttp://www.dmp.wa.gov.au/Safety/Guidance-about-hazardous-6930.aspx

6. Work Health and Safety Act 2011: https://www.legislation.gov.au/Details/C2017C00305

7. Model Work Health and Safety Regulations, released by Safe Work Australia and published November 28, 2016 by Parliamentary Counsel’s Committee

8. National Model Regulations for the Control of Workplace Hazardous Substances [NOHSC:1005(1994], National Code of Practice for the Control of Workplace Hazardous Substances [NOHSC:2007(1994)], National Code of Practice for the Preparation of Material Safety Data Sheets [NOHSC:2011(1994)], National Code of Practice for the Labelling of Workplace Substances [NOHSC:2012(1994)], Approved Criteria for Classifying Hazardous Substances [NOHSC:1008(1994)] and list of Designated Hazardous Substances [NOHSC:10005(1994)], Guidance Note: Assessment of Health Risks Arising from the Use of Hazardous Substances in the Workplace [NOHSC:3017(1994)]

9. Safety Data Sheet: Sulphuric acid with more than 51% acid, version 5, published by Ixom Operations Pty Ltd

10. Emergency eyewash and shower equipment, AS 4775, Council of Standards Australia

11. Emergency eyewash and shower equipment, AS 4775, Council of Standards Australia

12. Emergency eyewash and shower equipment, AS 4775, Council of Standards Australia

13. Emergency eyewash and shower equipment, AS 4775, Council of Standards Australia

14. Victorian WorkCover Authority, statistics published January 2018, covering period 01/01/1985 to 31/12/2017

15. Three men rushed to hospital after being burnt by scorching 450C molten metal in horror workplace accident, Daily Mail, December 18, 2017

16. Man suffers serious chemical burns after being sprayed with acid after tank bursts in Sunshine West, The Age, January 9, 2016

17. Nyrstar worker being treated at The Alfred’s burns unit in Melbourne, The Australian, July 19, 2017