-

Australia

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

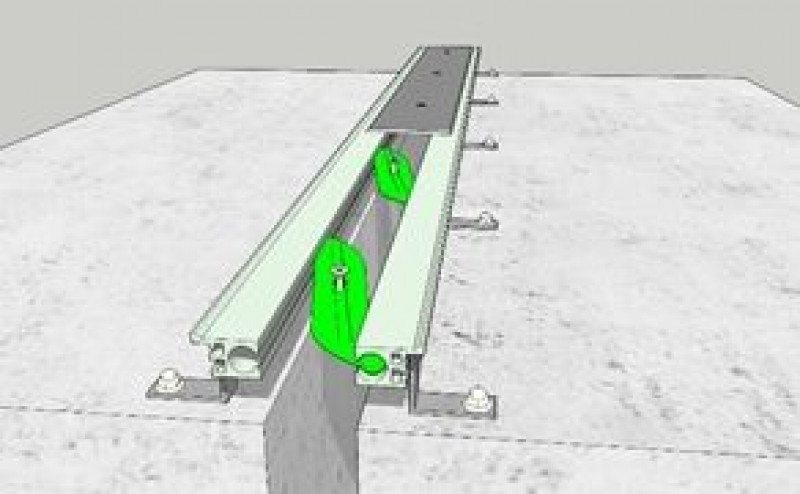

Most Australian designed mechanical expansion joint cover system consists of three fundamental components: Two base extrusions and a coverplate. The base sections for floors are generally fixed and grouted, or bonded to slab edges, either side of a movement gap. The coverplate is housed on, or in the base sections, and attached to them via centre-bars. The centre-bars are mated to each extrusion via ball and channel shapes. The centre of the c-bars are bolted to the coverplate via a machine screw. The c-bar ball-ends slide within the channel of base extrusions… rotating with movement. The machine screws keeps the coverplate central, above the two base extrusions whilst sliding over the top of them, and spanning the movement gap.

Traditionally centre-bars are made from spring steel, stainless steel, or other metal components. Whilst these materials can and do work quite well, there are often obstacles to overcome such as extended lead times, critical manufacture processes, corrosion.

Whilst there is still a place for c-bars made from metal materials, modern advances in injection moulding and composite ingredients have breathed new life into the 3-piece suspended-slab expansion joint system.

The engineers at Unison successfully developed a full range of centering bars manufactured from composite material. Unison’s range of centre-bars employs small medium and large composite c-bars; and a combination c-bar which is extendable. With this range of c-bar Unison has capacity to provide movement joint systems with coverplates ranging from 50mm to 1200mm.