-

Hong Kong SAR

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

19 Aug 2022 by SIGNIFY Hong Kong ( PHILIPS | HUE | interact )

The global industrial base is due for an upgrade. As the climate crisis intensifies, the industrial sector needs a comprehensive “green" renovation of the infrastructure it requires to make the things that businesses and consumers use.

Transformation doesn't have to be wrenching, though. Some of the available means for creating a sustainable industrial future are relatively easy. Just as importantly, such means can provide benefits to organizations that go beyond the goal of reducing environment impact.

In the traditional method of lighting procurement, organizations purchase and maintain their own lighting equipment for illuminating their properties: potentially thousands of luminaires and the wiring, controllers, servers, gateways, switches, sensors, and other infrastructure components required to operate and manage them.

Light-as-a-service (LaaS) turns this model around. In an LaaS arrangement, companies “rent" light from a lighting provider on a recurring subscription basis, instead of owning the lighting gear themselves. The lighting provider retains ownership of the equipment, and largely bears responsibility for maintaining and upgrading it.

Companies that embrace LaaS can rest easy, knowing they don’t have to worry about the practical responsibilities of owning their own lighting—all those luminaires to monitor and repair, all those lighting performance targets to hit, all that supporting hardware to maintain. In addition, under a LaaS agreement, companies can shift Capex costs from purchasing and owning lighting systems into operational costs that have a lesser impact on the balance sheet, improving free cash flow.

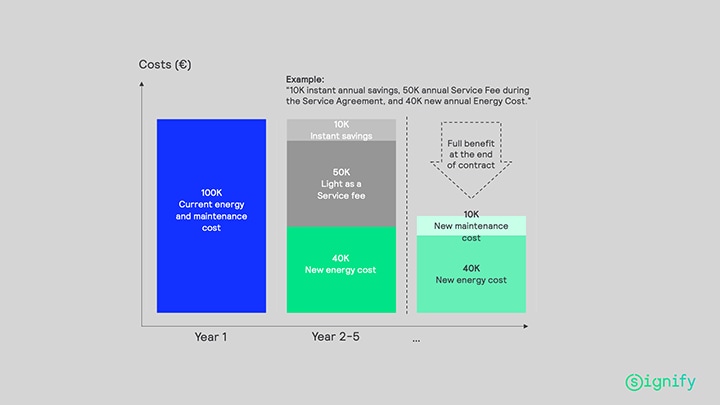

The chart below shows how adopting LaaS can save a company 10 percent of what it would have paid in energy and maintenance costs had it continued to own its lighting over the first five years of operation. By the sixth year, the company is saving 50 percent of those costs.

This chart also makes clear the startling results that LaaS can deliver in terms of generating free cash flow.

Fewer burdensome capital assets, relief from the labor- and capital-intensive “busywork" of ownership, and free cash flow: these are valuable benefits for any organization. But they aren't the only advantages that LaaS brings.

The best LaaS platforms are defined by connectivity. In addition to providing traditional illumination functions, a connected lighting platform serves as an ideal foundation for deploying Internet of Things (IoT) capabilities—often in the form of a combination of sensor technology and data analytics. Like any connected lighting system, an LaaS system with embedded sensors can collect information from every square foot of the illuminated environment. Transmitted securely to the cloud and analyzed, collected data can inform key management decisions.

Using the insights derived from occupancy and presence data, for example, a logistics facility can organize its stock to accelerate order picking. A manufacturer can better deploy raw materials and workstations. That same manufacturer can optimize its office footprint to minimize real estate costs while ensuring employee satisfaction.

At the extreme, numerous IoT-enabled industrial facilities can function more or less autonomously, with oversight exercised remotely—an important capability in a world trying to cope with the effects of a pandemic. More IoT-enabled capabilities will become mainstream as the technology inevitably improves, sensing becomes more precise, analysis becomes deeper, and open APIs make integration of smart systems easier.

IoT capabilities can also make facilities more pleasant and safe for workers. Context-responsive lighting results in better task performance, fewer manufacturing rejects, and perhaps most importantly, fewer accidents.

LaaS can benefit the climate by making industrial facilities more sustainable. More efficient IoT-enabled industrial processes mean smaller carbon footprints. Smart lighting that dims itself when natural light floods a facility is much more energy-efficient. Luminaire-hosted sensors that can signal in advance when they need maintenance, avoiding unplanned shutdowns that degrade efficiency, help the climate too.

A connected lighting system can also keep track of energy savings, identifying both efficiencies and problem areas. Managers can tweak settings and compare how different facilities are consuming energy. Measurement is the prelude to improvement—and measuring accurately will improve things more effectively.

Reporting also helps organizations comply with efficiency regulations that will only proliferate as the global climate response intensifies. And reporting makes it easier acquire LEED and other well building certifications, potentially boosting real estate values, and triggering green subsidies and tax breaks.

Certain kinds of facility are well positioned to realize free cash flow after switching over to LaaS. Prime candidates

If you’re considering a switch to LaaS, be aware that the transition process may present challenges. Procuring a service is different from procuring a product, and may require the early involvement of corporate attorneys. Legal teams may need to assess outcome-based service-level agreements more closely than they would standard purchase terms and conditions.

Accounting is another area that will likely require attention. The technical accounting teams will want to work with the legal team to ensure that a LaaS agreement is a true service agreement. That's important: the correct legal set-up can make possible an off-balance-sheet treatment, with all its advantages.

In terms of operations, it’s important to define a clear responsibility matrix for your teams. Engaging with a single trusted partner is the easiest way to go: you can avoid grey areas in assigning ownership for lighting deployment, functioning, and maintenance.

The LaaS approach is transformative. It promises to make industrial facilities more efficient, financially sound, and safe—not to mention more productive of free cash flow. It also serves as an ideal jumping-off point for the kind of sustainability-minded renovations that the industrial and manufacturing sectors must embrace, and soon.