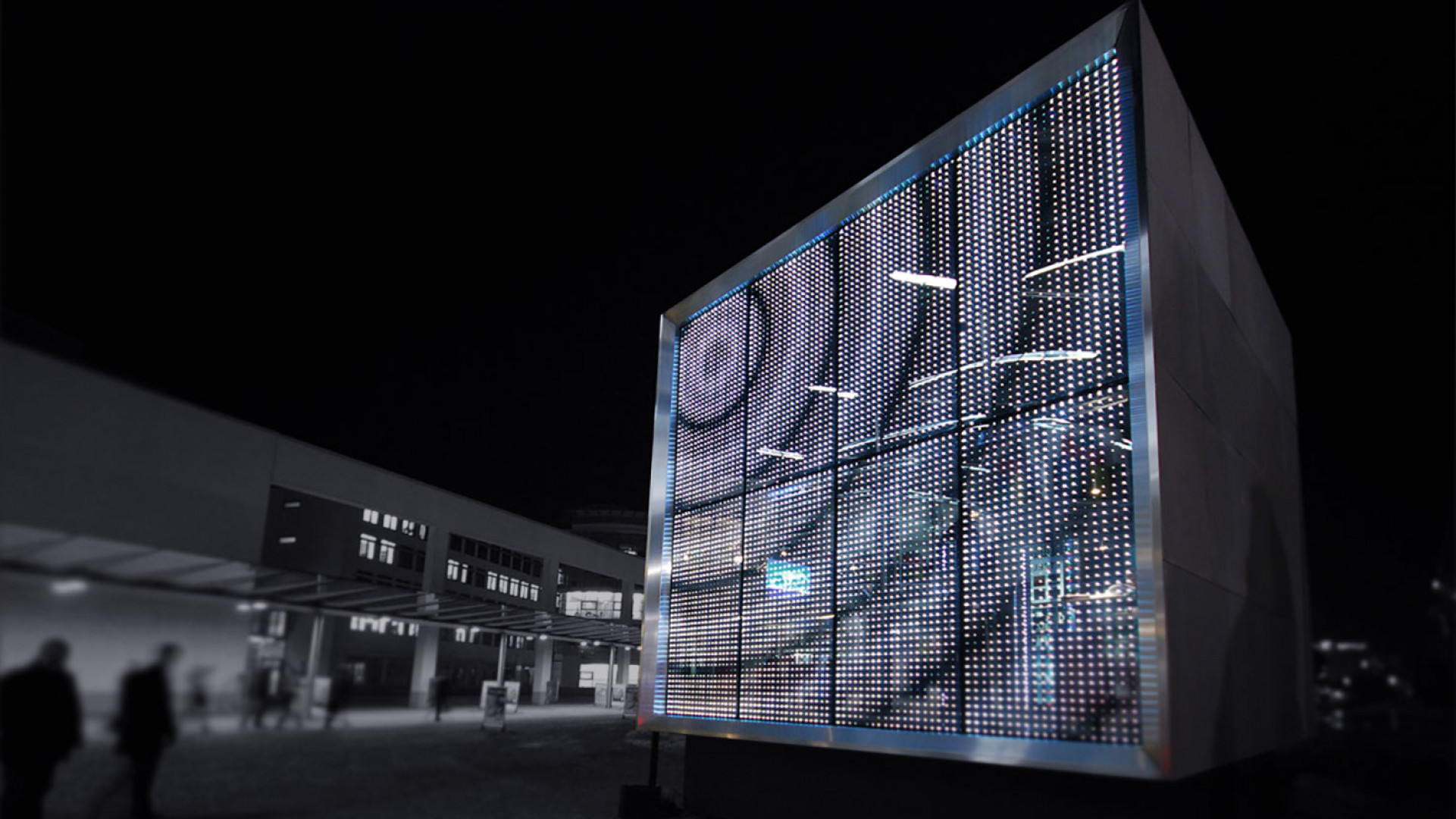

High tech in glass

LED inside the resin laminated glass are being supplied with electrical power via invisible circuits on the inner glass surface. Nearly any number and distance of LED is possible. Two contact bars, usually located along the long glass edges, are used to feed power into the conductive glass surface. An external power supply is always included.

LED lighting technology

Further development of LED - lighting technology made it possible to merge glass and light without wires into powerglass® and generate fascinating light effects. Light emitting diodes embedded in cast resin composites offer a variety of advantages:

- can be positioned nearly arbitrarily within the glass construction

- wireless power supply

- light radiating on both sides

- low power consumption

- marginal heat development

- protected within the resin composite

powerglass® in use

Peter Platz Spezialglas produces powerglass® according to your specifications. From cutting the glass to the final inspection - the entire production takes place in our own plant at Wiehl-Bomig.

The completed powerglass® panels come with pre-wired connecting cables (protection against ESD damage) and power supplies.

For further processing of powerglass® please note:

- assembly by professional services only

- please observe suitable storing and transport of glass

- do not put pressure on the surface

- only use specially coordinated sealing compounds recommended by us

- store and assemble ESD protected only

- circuit points and power supply must be serviced on a regular basis

- clean only with mild, standard window cleaner

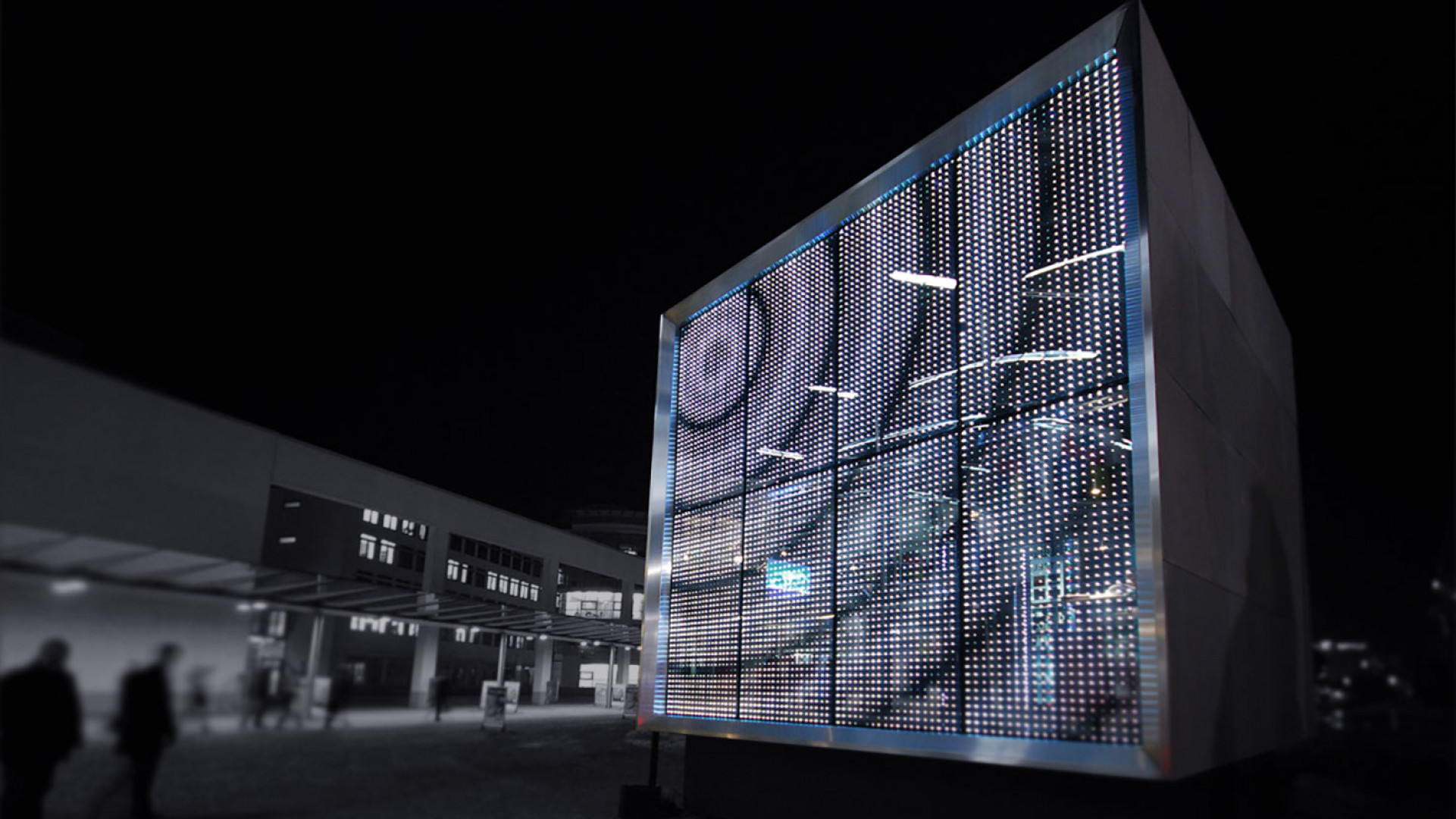

High tech in glass

LED inside the resin laminated glass are being supplied with electrical power via invisible circuits on the inner glass surface. Nearly any number and distance of LED is possible. Two contact bars, usually located along the long glass edges, are used to feed power into the conductive glass surface. An external power supply is always included.

LED lighting technology

Further development of LED - lighting technology made it possible to merge glass and light without wires into powerglass® and generate fascinating light effects. Light emitting diodes embedded in cast resin composites offer a variety of advantages:

- can be positioned nearly arbitrarily within the glass construction

- wireless power supply

- light radiating on both sides

- low power consumption

- marginal heat development

- protected within the resin composite

powerglass® in use

Peter Platz Spezialglas produces powerglass® according to your specifications. From cutting the glass to the final inspection - the entire production takes place in our own plant at Wiehl-Bomig.

The completed powerglass® panels come with pre-wired connecting cables (protection against ESD damage) and power supplies.

For further processing of powerglass® please note:

- assembly by professional services only

- please observe suitable storing and transport of glass

- do not put pressure on the surface

- only use specially coordinated sealing compounds recommended by us

- store and assemble ESD protected only

- circuit points and power supply must be serviced on a regular basis

- clean only with mild, standard window cleaner

High tech in glass

LED inside the resin laminated glass are being supplied with electrical power via invisible circuits on the inner glass surface. Nearly any number and distance of LED is possible. Two contact bars, usually located along the long glass edges, are used to feed power into the conductive glass surface. An external power supply is always included.

LED lighting technology

Further development of LED - lighting technology made it possible to merge glass and light without wires into powerglass® and generate fascinating light effects. Light emitting diodes embedded in cast resin composites offer a variety of advantages:

- can be positioned nearly arbitrarily within the glass construction

- wireless power supply

- light radiating on both sides

- low power consumption

- marginal heat development

- protected within the resin composite

powerglass® in use

Peter Platz Spezialglas produces powerglass® according to your specifications. From cutting the glass to the final inspection - the entire production takes place in our own plant at Wiehl-Bomig.

The completed powerglass® panels come with pre-wired connecting cables (protection against ESD damage) and power supplies.

For further processing of powerglass® please note:

- assembly by professional services only

- please observe suitable storing and transport of glass

- do not put pressure on the surface

- only use specially coordinated sealing compounds recommended by us

- store and assemble ESD protected only

- circuit points and power supply must be serviced on a regular basis

- clean only with mild, standard window cleaner

Hong Kong SAR