-

Malaysia

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

01 Oct 2019 by Dowsil

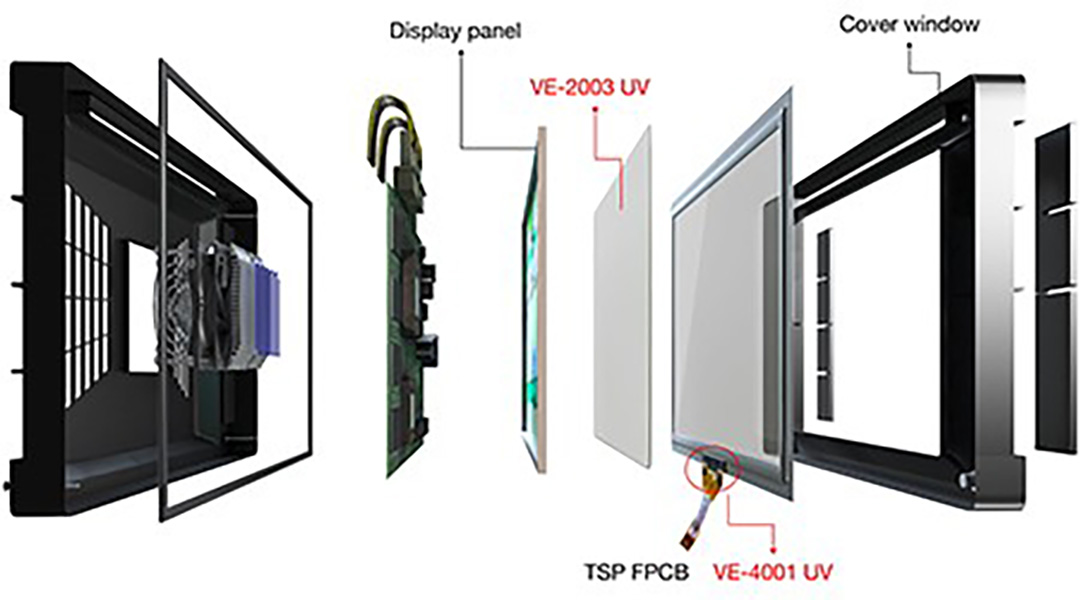

Dow Performance Silicones, a global leader in silicones, silicone-based technology and innovation is unveiling at CES Asia 2019 (booth N1-1014) two new optical bonding solutions for automotive and consumer displays exposed to harsh environmental conditions. They include DOWSIL™ VE-2003 UV Optical Bonding Material, designed to bond a glass or plastic display cover and touch panel to the LCD or OLED display module, and DOWSIL™ VE-4001 UV Electrode Protective Resin, which protects electrodes on the display module.

"As interactive displays in connected vehicles play an increasingly vital role in safety, navigation and entertainment, consumers expect an exceptional user experience,” said Jayden Cho, global consumer marketing segment leader, Dow Performance Silicones. “These displays must sustain their performance over the vehicle lifespan, under the demanding conditions of automotive interiors. DOWSIL™ VE Optical Bonding Materials deliver better readability, visibility and reliability compared to traditional organic materials, support new designs and easily adapt to existing optical bonding processes. Dow will continue to address our customers’ demands for higher-performing optical bonding solutions to meet the requirements of tomorrow’s increasingly sophisticated displays.”

These robust silicone-based materials represent the newest generation of DOWSIL™ VE Series optically clear resins, whose excellent optical properties help automotive and consumer displays deliver exceptional performance. Their benefits include high transmittance, low haze, minimal yellowing and superior reliability, even when subjected to temperature extremes, high humidity and prolonged UV exposure.

The automotive display market is projected to grow at a CAGR of over 10 percent through 2025, with 350 million units globally expected to ship by that date.1 Top design trends include the integration of touchscreens, larger displays, curved screens and heads-up displays.

Reliable Optical Bonding

Environmental reliability test conditions in the automotive industry, including high-temperature degradation, thermal shock and humid heat constant, have become more stringent in recent years, calling for increasingly reliable optically clear resins.

In direct response to this challenge, Dow developed the new DOWSIL™ VE Series materials. DOWSIL™ VE-2003 UV Optical Bonding Material is a transparent, solventless, one-part UV-curable solution used to bond a cover window and touch panel made from glass or plastic, such as polymethyl methacrylate (PMMA) or polycarbonate (PC), to the display module. It is engineered to resist degradation and yellowing from ultraviolet (UV) exposure and from high and low temperature extremes and humidity. The material delivers consistent optical transmittance greater than 99 percent before and after reliability testing.

DOWSIL™ VE-2003 UV Optical Bonding Material offers excellent adhesion, self-leveling flowability, low modulus to avoid mura effect, and low shrinkage (less than 1.0 percent) for dimensional stability – especially in larger displays. It can cure to an extremely soft material which helps provide cushioning and stress relief for delicate components.

Benefits of an All-silicone Solution

Using a silicone-based solution for both electrode protection and optical bonding optimizes reliability of display modules, whose mechanically sensitive electrodes can be affected by moisture, heat, impact, and especially UV light. It also avoids incompatibility issues arising from the combination of silicone optical bonding with organic electrode protective resin (EPR). This can lead to failure in solar testing and cause haze, yellowing and softening of the silicone OCR under high temperatures (up to 105 °C) and UV levels in automotive interiors.

To offer the industry a compatible, silicone-based EPR for use with DOWSIL™ VE-2003 UV Optical Bonding Material, Dow developed DOWSIL™ VE-4001 UV Electrode Protective Resin. This new solution offers high reliability including consistent hardness and adhesion before and after testing, thanks to its low volatility. The cured material provides stress relief for sensitive components.

DOWSIL™ VE-4001 UV Electrode Protective Resin is a translucent, one-part, UV-curable silicone resin designed for liquid-based bonding processes and is available worldwide.

To learn more about this growing portfolio of optically clear resins, please contact Dow.

1 Source: https://www.gminsights.com/industry-analysis/automotive-display-market

About Dow Performance Silicones

Dow Performance Silicones delivers a portfolio of performance-enhancing solutions to serve the diverse needs of customers and industries around the world. The business uses innovative silicon-based technology to provide solutions and ingredients to customers in commercial construction and high-performance building, consumer goods, silicone elastomers, and pressure sensitive industries. As a global leader in innovation and silicone technology, we are committed to bringing new and proven solutions to the market that do more for our customers and continue to improve the lives of consumers worldwide. Visit consumer.dow.com to learn more.

About Dow

Dow (NYSE: DOW) combines one of the broadest technology sets in the industry with asset integration, focused innovation and global scale to achieve profitable growth and become the most innovative, customer centric, inclusive and sustainable materials science company. Dow’s portfolio of performance materials, industrial intermediates and plastics businesses delivers a broad range of differentiated science-based products and solutions for our customers in high-growth segments, such as packaging, infrastructure and consumer care. Dow operates 113 manufacturing sites in 31 countries and employs approximately 37,000 people. Dow delivered pro forma sales of approximately $50 billion in 2018. References to Dow or the Company mean Dow Inc. and its subsidiaries. For more information, please visit www.dow.com or follow @DowNewsroom on Twitter.