Natural vs Quartz vs Porcelain Stone

With the wide range of stone selections on the market today, the differences can be overwhelming when deciding on a stone product that matches your application. As technology has progressed, stone manufacturers have continuously developed new and improved ranges of stone slabs to meet the consumers functional yet aesthetic requirements. Now, with endless options of quartz engineered stone available, a relative newcomer has joined the market; porcelain stoneware.

What does it mean for a material to be natural, quartz or porcelain?

Most stone materials can be classified into three main groups:

1. Natural Stone. This means that large blocks of raw stone are cut from a mountain or quarry, processed into slabs and sold to stone fabricators as natural marble, granite or quartzite slabs.

2. Quartz/Engineered Stone. For engineered surfaces, the same natural materials such as quartz are processed by compressing the material into a denser and less porous slab improving the durability and consistency of the slabs.

3. Porcelain Stoneware. To produce porcelain involves an even more technologically advanced production process as raw clays and materials are compressed then subjected to a firing process at over 1100 °C. Although the process is more advanced, the resulting surface is incredibly resistant to wear, mechanical stress and thermal stress.

So, what are the main differences?

1. Aesthetic Consistency

Although the beauty from natural stone is obvious, natural stone, or granite stone, always contains large variation in aesthetics. This is because each slab of natural stone is individually cut from granite quarry, making each granite slab, naturally unique. Other factors that reduce the consistency of natural stone is the quarry location, the climate and conditions that the stone has been formed. Even natural stone mined in the same location can vary hugely from batch to batch due to the previously mentioned conditions. The downside of this is the limitation to guarentee a consistent surface. On the flip-side, a natural stone benchtop will be different, and completely unique however we recommend you viewing the natural slab before confirming.

With quartz engineered stone, the quartz stone is extracted from mines, and then ground to a pure quartz stone. This stone is then pressed with resins and colourants to form a consistent, non-pourous and very durable surface. Quartz engineered stone is much more consistent aesthetically than natural granite, and as technology and experience advances, quality quartz stone manufacturers have been able to replicate the beautiful marble aesthetic found in granite but by using the crushed quartz and resin materials. The beauty of quartz is that it is full-bodied so the quartz colour and marble veining is carried through the entire 20mm or 30mm thickness of the quartz engineered stone slab.

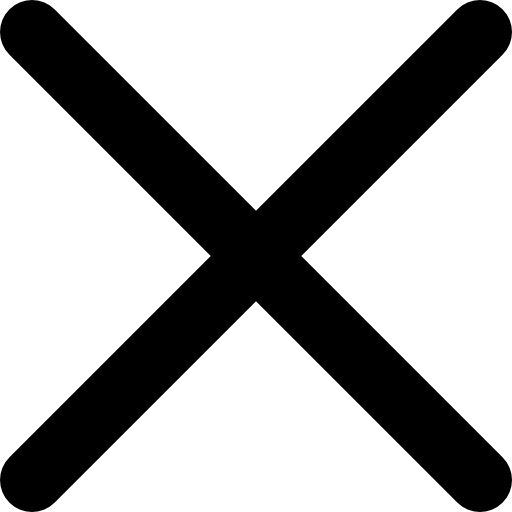

Finally, porcelain stone is possibly the most aesthetically consistent out of all granite and quartz stones. This is because the stone pattern is printed subliminally on the surface of the porcelain slab. This has allowed manufacturers to design the slab themselves, and then print each slab with absolute precision and exactness. As it is subliminally printed, the pattern is printed down into the surface, however the marble veining in porcelains are not full-bodied, so do not go through the entire thickness of the slab. This can be counter-acted by choosing a very thin 12mm benchtop style, or by creating a thick 30 - 40mm benchtop thickness by mitering the edge.

(Archant Quartz in Glacier Nova, a beautiful full-bodied marble quartz kitchen benchtop)

2. Durability & Performance

By processing raw materials to form an engineered slab or tile creates a much stronger and more durable slab compared to natural granite.

Throughout the manufacturing process of engineered man-made stones (such as quartz and porcelain), the quartz is heavily compacted with resins, resulting in an extremely non-porous and stain resistant surface. In natural granite, the stone is much more porous and stains easily, as the stone is cut from the mine, with no compaction or engineering applied. This means that natural granite stone is often not suitable for family kitchens where a range of liquids such as red wine, vinegar, juice are present which can easily stain or tarnish the natural granite.

Although engineered quartz stone benchtops non-porous, some of the matte and textured finishes can be slightly porous and require more maintenance such as drying your benchtop each day to ensure the liquids do not leach into the stone and stain.

Finally, porcelain is the most superior surface in terms of strength, durability and performance in kitchen or bathroom environments. This is due to its manufacturing process which not only involves finer ground quartz but also includes being processed through controlled furnace to give the surface more performance qualities. This means Archant Porcelain is not only 100% non-porous but is also scratch and stain resistant as well as being usable for outdoor environments with its UV resistance. The performance is porcelain is so durable, that Archant Porcelain, offers a lifetime warranty on residential kitchen applications of the surface!

Customisation

Your natural stone slab will be unique…just like a fingerprint, so there’ll always be an element of surprise with your natural stone slab. However, the engineered stone and porcelain ranges today can provide you nearly the same uniqueness. With widespread colour options available the end-user is also given guaranteed colour consistency as well as opportunities to customise your texture, finish, thickness and composition.

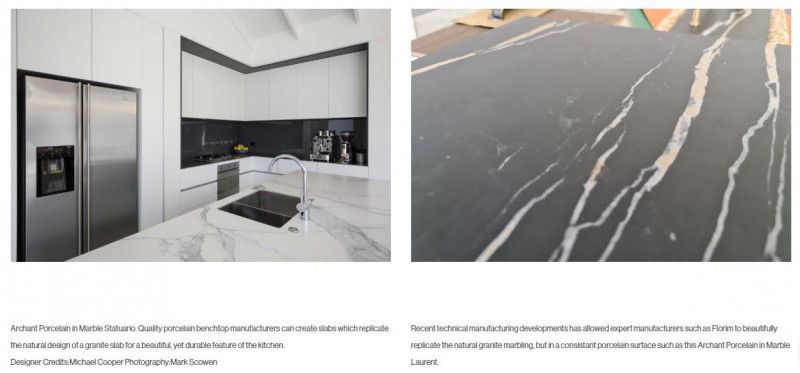

With some porcelains, the surfaces are subliminally printed onto for even greater customisation. In fact, Florim, a porcelain manufacturer produces a Marble Collection where the beautiful marble veining is created from the processing of natural materials.

So, what should I go for?

Each stone type varies in their aesthetics, performance, customisability and maintenance which allows you to choose the stone that best suits your lifestyle.

Natural stone is beautiful, raw and unique yet the maintenance to keep the surface looking pleasing must be considered. Pleasing to the touch, natural stone will have a natural undulating surface and texture in combination with its uniqueness.

Engineered stone and their wide range of consistent surface colours give you the opportunity to match your surface to cabinetry, sink ware, tapware or handle-ware. This stone type contains the natural texture of stone with less porosity, higher material performance and aesthetic consistency.

Finally, porcelain is perhaps the most forgiving and functional yet beautiful and customisable. This surface will maintain a consistent look over its long lifetime due to its strong resistance to any form of wear. Not only does porcelain boast material superiority but also offers possible range of choices guaranteeing attention to detail, stylistic research and tailoring.

Indonesia

Indonesia

Australia

Australia

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia