-

Singapore

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

Every day a significant amount of dirt and micro-organisms accumulates in the scratches and joints of busy flooring surfaces. Reducing this type of contamination is essential if the floor is to be kept scrupulously clean. Using traditional methods to remove it is almost impossible but, using Bona’s latest deep cleaning and recoating methods, floor owners can considerably improve the hygiene levels of their floors.

Many types of resilient flooring cover large areas and represent a ‘sealed’ surface with no breaks in the surface. Panels of the flooring are connected by plastic welds which keep the flooring intact and prevents the ingress of liquids into gaps and beneath the flooring. Over time welds can become damaged by wear and tear leading to difficulties cleaning the surface effectively. Broken welds or splits and tears to the flooring can be addressed using Bona’s PU Filler. This would be done during a full renovation using the Bona Resilient System.

This is an effective and cost-effective alternative to replacing the existing floor when it is considered to be at the end of its life. Along with the environmental and cost benefits, the process requires much less time compared to replacement, which with resilient flooring will always involve lengthy subfloor preparation in addition to the disposal of the removed flooring. A full renovation, which can include changing the colour and introducing logos etc, will result in the surface returned to its sealed state making maintenance more simple and effective in removing micro-organisms.

The Bona concept is to periodically deep clean and seal the floor’s surface, ideally from the time it is installed, to produce a smooth, homogenous surface which can be easily and efficiently cleaned during its lifetime. The sealing treatment, overcoating with Bona Pure, fills any fine cracks and scratches, as well as the joints between LVT panels – to eliminate the possibility of dirt and micro-organisms building up on the surface and making daily cleaning easier and more efficient.

Using safe, non-hazardous products from Bona’s Resilient Floor System range, the deep cleaning and recoating process also enables you to maintain the beauty of the floor and prolong its life – with minimal downtime during treatments. Recoating involves superficial sanding with a Bona FlexiSand machine using Bona Diamond Abrasives for a perfectly smooth surface. This is followed by an application of Bona Pure, a hard wearing, non-yellowing, clear polyurethane coating specially formulated for the treatment of resilient floor coverings. Floors treated with Bona Pure also meet the DIN 51130 (R9) standard for slip resistance.

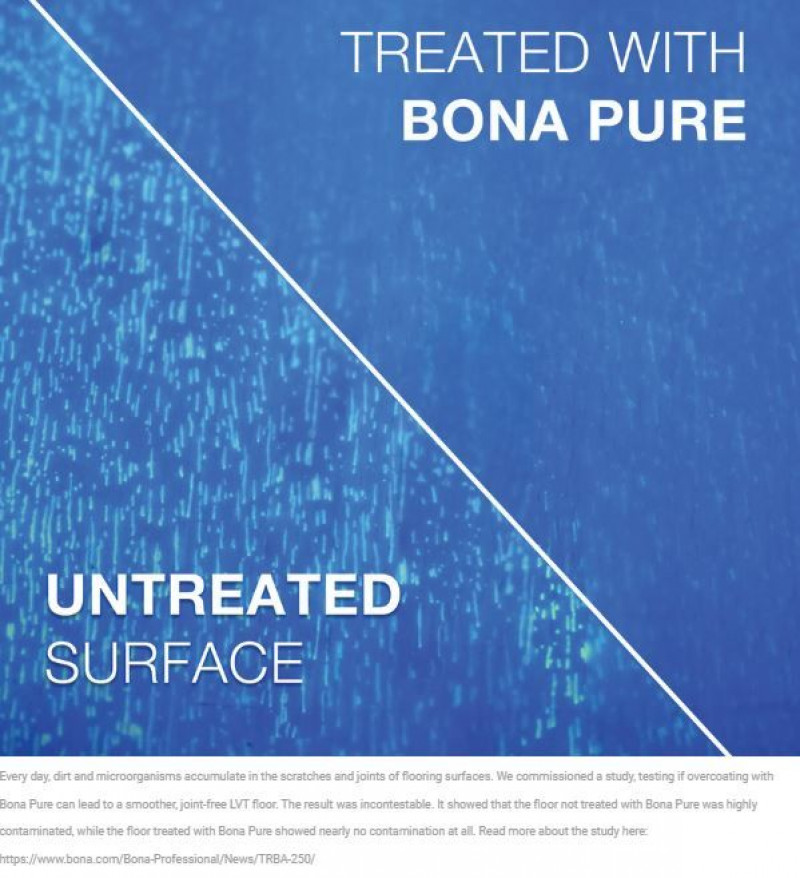

To prove the hygiene performance of the Bona recoating system, we commissioned a study of its use on LVT flooring – the type typically used in hygiene sensitive areas such as hospitals, clinics and dental surgeries etc. The test, carried out in conjunction with the IFR Institute in Germany, was to verify that a smooth, joint-free LVT surface can be created by overcoating with Bona Pure, achieving a surface that met the standards required by the internationally recognised TRBA 250 (Technical Rules for Biological Agents in Healthcare and Welfare Facilities).

The test involved coating one half of a new LVT wood effect plank floor with Bona Pure, while the other was left untreated. A solution containing fluorescent pigments was then applied daily across the whole floor and cleaned using the Bona PowerScrubber and Bona Deep Clean Solution. Daily contamination with the pigments, followed by cleaning, was carried out over a period of 8 weeks. At the end of the test period, UV lights were used to expose the levels of contamination on each part of the floor.

The part of the floor not treated with Bona Pure showed high levels of contamination. The part treated with Bona Pure showed hardly any. The LVT planks were then removed to examine for signs of contamination below the surface. On the untreated area, a high level of contamination was found below the planks due to penetration through the joints – and almost none on the part treated with Bona Pure.

By applying a coat of Bona Pure on an LVT floor meets the criteria defined in the TRBA 250 regulations. Its sealing power creates a barrier against residual germs and micro-organisms, making it easier to keep the floor scrupulously clean.

In addition to recoating with Bona Pure, the Bona Resilient Floor System offers a range of cleaning and long-term maintenance treatments for all types of resilient and wood surfaces. For example, there are options enabling the total transformation of a resilient floor by using Bona Pure Colour PUR based paint (available in any RAL colour), and the inclusion of graphics or logos etc below the final clear top coat.

The Bona Resilient Floor System not only allows you to improve floor hygiene, but also to totally transform the look of your existing floor without replacing it. Recently this process was used to refurbish the floor within a busy dental practice.