-

Singapore

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

Epoxy floors are durable, easy to clean and maintain. Moreover, it looks great with the seamless appearance and ability to customize in various colours. However, issues such as chipping or cracking may occur.

The extent of repair will depend on the type of cracks. First, let us look at the causes of floor cracks.

Presence of water or damp can cause existing resin coating to bubble and result in debonding from the substrate. When heavy loads come into contact with the affected surface, the bubble may crack. Machine vibration can also cause the epoxy coating to debond from the substrate.

Impact from falling objects and point load can cause depression or floor surface to be chipped off.

Crack originates from the substrate. Shrinkage cracks to the substrate during curing process decreases the volume of concrete mass due to evaporation of water content, and force the concrete to develop cracks in the weaker parts.

Once we have determined whether it is a surface crack or one that originates from the substrate, we can implement the appropriate repair method.

In all cases, mechanical surface preparation has to be done before fixing any holes, joints and surface defects. The first step is to detect any hollowness around the crack and isolate the area by placing a tape. Hollowness on the floor can be detected using a mallet or any other tool such as a metal or steel object to tap on the floor. The sound produced from a hollow substrate is different from the bonded substrate. If there is hollowness, the affected areas have to be removed and grinded off and proceed with localized repair.

If it is just a surface crack (e.g. crack in the coating), repair can be done by removing loose/weak particles and coating from the cracks and joints, and then made sound. This is followed by grinding off the existing coating and then applying a primer and finishing coat.

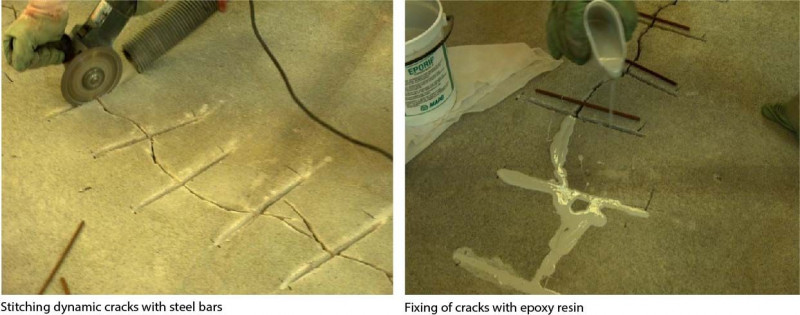

If the crack arises from the substrate, all loose particles around the crack have to be removed and made sound. The cracks are then patched and fixed with fluid epoxy resin such as Eporip or an epoxy resin such as Primer SN mixed with Additix PE. An option is to embed a fiber mesh to help avoid or reduce capillary crack in case of micro-contractions.

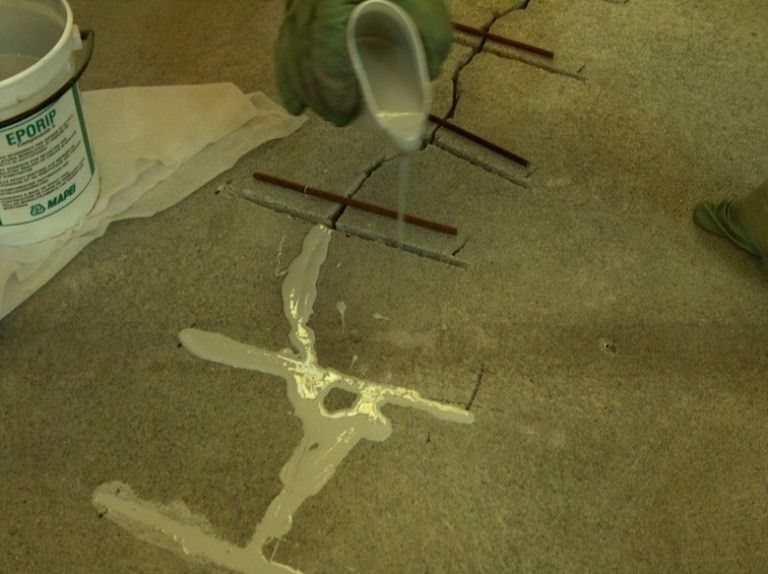

For dynamic cracks that come from the concrete substrate (i.e. screed has debonded from the concrete substrate), a localized repair can be done by removing all friable weak parts from the cracks and joints. If necessary, enlarge the cracks with a cutting tool and clean with a vacuum cleaner. Next, perform “stitching” or cross cuts along the cracks. The stitch can be further reinforced with steel bars to reduce their contraction or expansion width. Steel bars are placed into the opening and embedded with fluid epoxy resin to close the crack. Subsequently, the surface has to be grinded flat.

If the surface needs to be further reinforced, a fiber mesh can be applied such as Mapenet 150. The surface is then embedded and fixed with a primer (for instance, Primer SN added with Additive PE) to smoothen the floor. This is followed by sanding and then applying a finishing coat. For holes and joint edges having higher thickness, these can be repaired or patched with heavy-duty epoxy mortars such as Mapefloor EP 19 MT with a minimum thickness of 5mm.

Queries? Contact Mapei Singapore for consultation or your project needs.

____

About Mapei:

Founded in Milan since 1937, Mapei is today a world leading producer of adhesives and complementary products for the laying of all types of floor, wall and coating materials. Mapei’s specialty lies in products for ceramics and stone materials, among other product lines. Mapei’s adhesives for tiles and stones are certified according to international standards and are SGBC certified. Experience proven by numerous notable projects worldwide.

Related articles:

How to avoid blistering in resin flooring

Industrial flooring: What is the difference between Epoxy and Polyurethane

Non-shrink grouts vs Patch repair mortars: how are they different?