-

Singapore

Copyright © 2025 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

The construction and building industry are in rapid development and it creates a growing environmental footprint. Even nowadays construction materials are responsible for more than one third of global resource consumption. (1) and around 30% of the global energy (2)

What is more, buildings generate significant amounts of waste, in fact 40% of the generated urban solid waste (3) and only 20–30% of construction and demolition waste (CDW) is recycled or reused, which is often due to poor design and lack of information on building contents. (4)

From linear to circular models

The traditional linear economic approach is based upon the principles of take-make-use. Where the resource supply from the construction sector led to enormous emissions and waste. With that said, there is an urgent need to go back and implement a more circular approach that helps reduce emissions and waste. The circular economy follows the principle of reduce-remake-recycle similar to how the natural and biological system works so it’s not something new for the environment.

A circular economy relies on three principles:

1. Design out waste and pollution

2. Keep products and materials in use

3. Regenerate natural systems

Design out waste and pollution

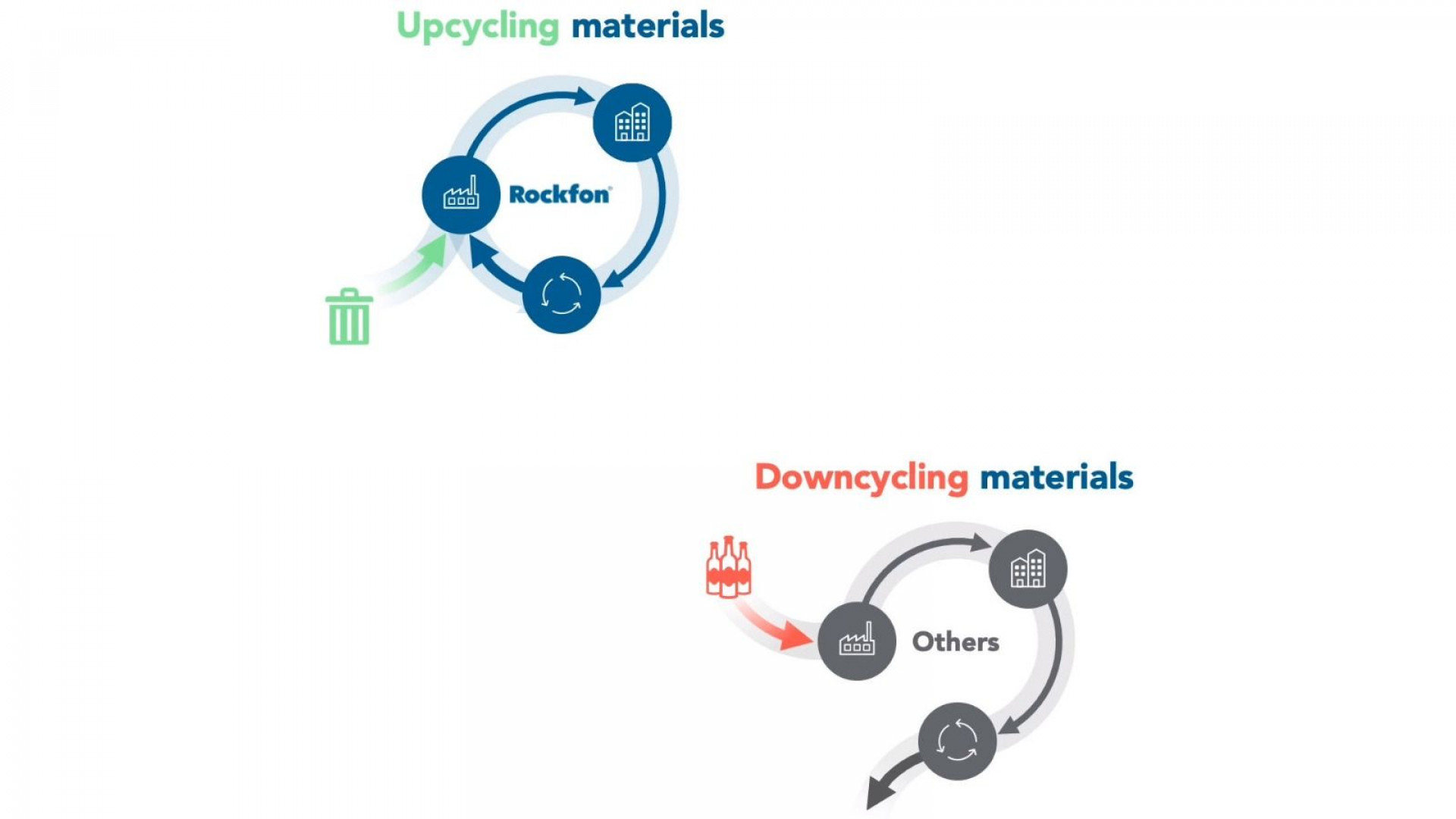

For the built environment is concerns many things so you’ve the opportunity to get started. It could concern selecting products with low environmental footprint, products that don’t hold any toxic substances and don’t cause any significant burden to the environment. It could also cover the design of the building and its materials. They should be flexible and modular so they easily can be disassembled and dismantled to be used within the same or other function. This means that products are easily be recycled if they aren’t reused and even better upcycled to create materials and products of higher value. It can also be related to the content of the materials and the effort to have the highest recycled content as possible meaning that the products and systems reduce the use of primary resources with the aim to include as many secondary materials as possible.

Keep products and materials in use

The second one is about keeping products, components and materials at their highest value and in use. This aspect concerns two of our key aspects: durability and long-lasting life-circle.

Durability of the construction materials in the built environment covers the importance of selecting materials and products with a long-lasting performance. It shouldn’t degrade, need maintenance or replacement. If a product is durable, it consumes less energy and are more profitable for the building.

The long-lasting life-circle covers the end-of-life options of the materials. It’s very important to choose materials that are easily recycled if they aren’t reused and even better upcycled to create materials and products of higher value.

Looking at the content of the materials, it’s important to make sure that the products selected have the highest recycled content possible to as much as possible to minimise the use of primary resources.

The benefits of this approach are that you’ll manage to reduce the CO2 emissions from remanufacturing, reduce the resource demand and energy use. A significant benefit is also in terms of costs as you don’t have to consider any repair or renovation costs, or the cost of any raw materials.

Regenerate natural systems

The third and final aspect is about regenerating natural systems. It could be that you create and design buildings that are passive and bioclimate, where the design should strive to be “biophilic” securing the wellbeing of the occupants.

Inspired by Edward O. Wilson's hypothesis that humans have an inherent need of nature, Biophilic Design seeks to enhance our connection with the natural environment. Biophilic design incorporates natural elements into workplace design that can include: access to natural light, natural colours, patterns and textures. In that context, selecting materials that enhance the natural light and secure good acoustics and indoor conditions is key. Regenerating natural systems could also be other things like how the product returns to the environment in the end of its lifetime.

Learn more about transforming waste into more valuable products here: https://en.rockfon.international/sustainability/our-lifecycle-approach/recycling/

Why is it important?

It’s never been more important to design buildings for the circular economy. And the construction industry diverts 1-2 billion tonnes of waste, or one-third of the global total waste to landfill, and that’s something we need to take seriously.

We’re all about the circular economy and minimising the emissions and waste of the take, make and dispose model commonly found in the construction industry. Our acoustic solutions are made up of anywhere between 29% up to 64% of recycled materials and we do not use any scarce resources.

After installation we can collect and recycle the cut-offs and when it's time to retire our grids and acoustic ceiling solutions, we can do that too. We turn our products into new durable solutions again and again without affecting the quality or down-cycling them into other products with lower value.

What makes Rockfon products circular

By looking into the previous definition from Ellen Mac Arthur we can say that we fulfil all the three criteria for a circular product.

We design out waste and pollution during the whole life cycle of stone wool, we keep the product in use for a long time and we regenerate natural systems.

During manufacturing, we upcycle waste from other industries and create value, stopping these materials from being sent to landfill. Our stone wool products are made from up to 50% recycled materials. Additionally, we don’t use any scarce resources or don’t divert any scares resources away from other industries and none of our factories send stone wool waste to landfill Basalt is an inexhaustible raw material: every year the earth produces 38,000 times more volcanic rock then ROCKWOOL uses in a year.

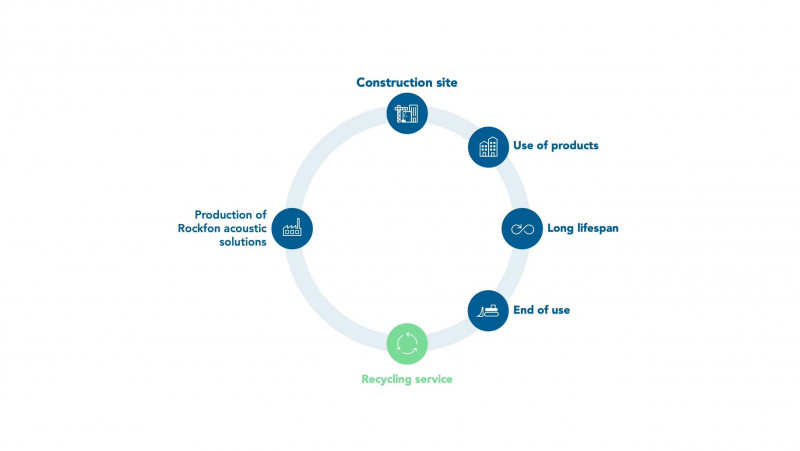

During its installation we offer the chance to recycle the stone wool waste cut-offs by delivering it back to our factories. By this, the product stays in the building for a long lifespan and keeps the same technical properties and functions as the day you installed it. Stone wool tiles and grids can be reused and therefore have a second or third life cycle. During its useful life, stone wool acoustic solutions can be easily dismantled and can be recycled again and again without any degradation on its quality and not, for example, down-cycled into other products with lower value.

At Rockfon, we keep the loop closed as ww offer a recycling service in many European countries where we have business activity. We support our customers by taking back our ceiling tiles to our established partnerships with waste handling companies. With us, you’ll have a sustainable partner. We’ll recycle it again and again to create sustainable buildings that are more efficient, healthy and durable.

Download our “8 facts about the circularity of stone wool ceiling tiles” here: Link

References:

(1) OECD, Working party on resource productivity and waste: a policy study on the sustainable use of construction materials (2015) p. 4)

(2) p. 14; International Resource Panel, The weight of cities (2018)

(3) World Bank, What a waste: a global review of solid waste management (2012) p. 16

(4) Ellen MacArthur Foundation, Towards the circular economy (2013) p. 16; M. Honicet et al., Data- and stakeholder-management framework for the implementation of BIM-based material passports, Journal of Building Engineering (2019) ).

For more information, please visit us @ en.rockfon.international.